Inventory management is the process of controlling and overseeing stock—raw materials, finished products and everything in between.

If you’ve landed on this article, then we’re willing to bet that you’re looking to learn more about stock control. Maybe you’re struggling with stock control and want a better handle on your inventory levels and order processes. Perhaps you’re experiencing issues like overstocking or running out of key items at crucial times.

By ensuring you have the right quantity of items available at the right time, inventory management directly affects profitability, efficiency and customer satisfaction. Without proper control, businesses face costly risks like overstocking, stockouts and delayed deliveries, which can severely damage your bottom line. In fact, studies show that retailers lose at least $1.75 trillion each year globally due to mismanaged inventory, including overstocks, out of stocks and preventable returns.

Effective inventory management gets you ahead of these costs with increased accuracy and better demand forecasting. But that’s easier said than done—maintaining the balance between supply and demand while planning for everything that could (and will) go wrong requires a deft hand.

In this blog, we’ll go over everything you need to know to hit the sweet spot for your business:

- What is inventory management?

- Benefits of inventory management

- Challenges in inventory management

- Inventory management software

Inventory Spreadsheet Template

Download this free inventory spreadsheet to help you better manage your stock, purchases and sales.

What is inventory management?

First, a definition: inventory management is what’s involved in the process of overseeing and controlling a company’s stock, ensuring the right products are available at the right time to meet customer demand while minimizing excess and costs.

It involves tracking inventory throughout its lifecycle:

The importance of inventory management is directly related to avoiding issues like overstocking, stockouts and operational delays, all of which can affect profitability and customer satisfaction.

Inventory is typically divided into four categories, and each has different inventory management methods.

| Type | Description | Management Tips |

| Raw materials | Basic components used in the production process. | Track based on production schedules. Ensure just-in-time (JIT) delivery. |

| WIP | Goods in the process of being manufactured but not yet complete. | Use production tracking systems. |

| Finished goods | Products ready to be sold to customers. | Maintain accurate stock count. Prioritize efficient storage. |

| MRO | Supplies used to keep production running smoothly. | Keep parts organized and track usage to prevent shortages. |

Raw materials

Raw materials are the basic components used in the production process, such as fabrics in the fashion industry or metals in manufacturing.

Managing this inventory involves tracking raw materials based on production schedules and ensuring just-in-time (JIT) delivery to avoid overstocking. Retailers should regularly review supplier performance to ensure timely replenishment.

Work in progress (WIP)

WIP refers to goods that are in the process of being manufactured but are not yet complete.

WIP inventory needs to be monitored through production tracking systems to optimize workflows and reduce bottlenecks. This ensures efficient movement between production stages to minimize delays and inventory build-up.

Finished goods

Finished goods are products that are ready to be sold to customers.

When managing finished goods, you need to proactively maintain accurate stock counts and prioritize efficient storage to ensure quick access for fulfillment. Regularly review sales data to align stock levels with customer demand and avoid excess inventory.

Maintenance, repair and operations (MRO) inventory

Businesses may also track (MRO) inventory, which includes supplies used to keep production running smoothly.

Management in inventory for MRO supplies includes keeping parts well-organized and tracking usage to avoid unexpected shortages.

Benefits of inventory management

- Cost control

- Improved cash flow

- Customer satisfaction

- Operational efficiency

- Data-driven decisions

Cost control

Effective inventory management helps reduce both holding and ordering costs by maintaining optimal stock levels.

Overstocking leads to higher carrying costs, such as storage fees, insurance and spoilage—spoilage alone costs food and beverage retailers $70 million annually. On the other hand, understocking can result in frequent emergency orders, which increase ordering costs due to rush shipping or missed bulk discounts.

By accurately forecasting inventory demand and adjusting stock levels accordingly, businesses minimize the financial strain from excess inventory and avoid the costly consequences of stockouts, thereby optimizing their overall expenses.

Improved cash flow

Optimized inventory levels directly enhance cash flow by preventing capital from being tied up in excess stock.

When businesses manage their inventory efficiently, they only purchase what is necessary, allowing them to allocate more funds to other critical areas such as marketing, product development or debt reduction.

Quick inventory turnover ensures that products move through the supply chain at a healthy pace, generating revenue faster and keeping the business financially healthy and agile.

Customer satisfaction

Inventory management plays a vital role in ensuring that businesses meet customer demand in a timely manner.

Accurate stock levels reduce the likelihood of backorders and delayed shipments, both of which can harm customer loyalty and satisfaction. When customers receive their orders on time and without issue, their confidence in the brand grows.

Operational efficiency

Streamlined inventory management optimizes warehouse processes, reducing waste and improving resource allocation.

By keeping stock levels organized and updated, employees spend less time locating items, fulfilling orders and managing returns. This efficiency reduces unnecessary labor costs and minimizes the risk of errors, leading to faster order fulfillment and overall smoother operations.

Data driven decisions

Accurate inventory data allows businesses to make informed strategic decisions.

By analyzing sales trends, stock levels and customer demand, companies can identify which products to reorder, when to reduce stock, or how to forecast future trends. This data-driven approach helps businesses anticipate shifts in the market, optimize their supply chains, and respond to customer needs proactively.

Challenges in inventory management

- Demand forecasting

- Supply chain disruptions

- Overstocking and stockouts

- Inventory visibility

- Technology integration

Demand forecasting

Accurately predicting customer demand is a major challenge in inventory management. Fluctuations in customer preferences, seasonality and market trends can make it difficult to forecast how much stock to carry.

Overestimating demand can lead to overstocking, while underestimating it can cause stockouts. Both scenarios hurt profitability.

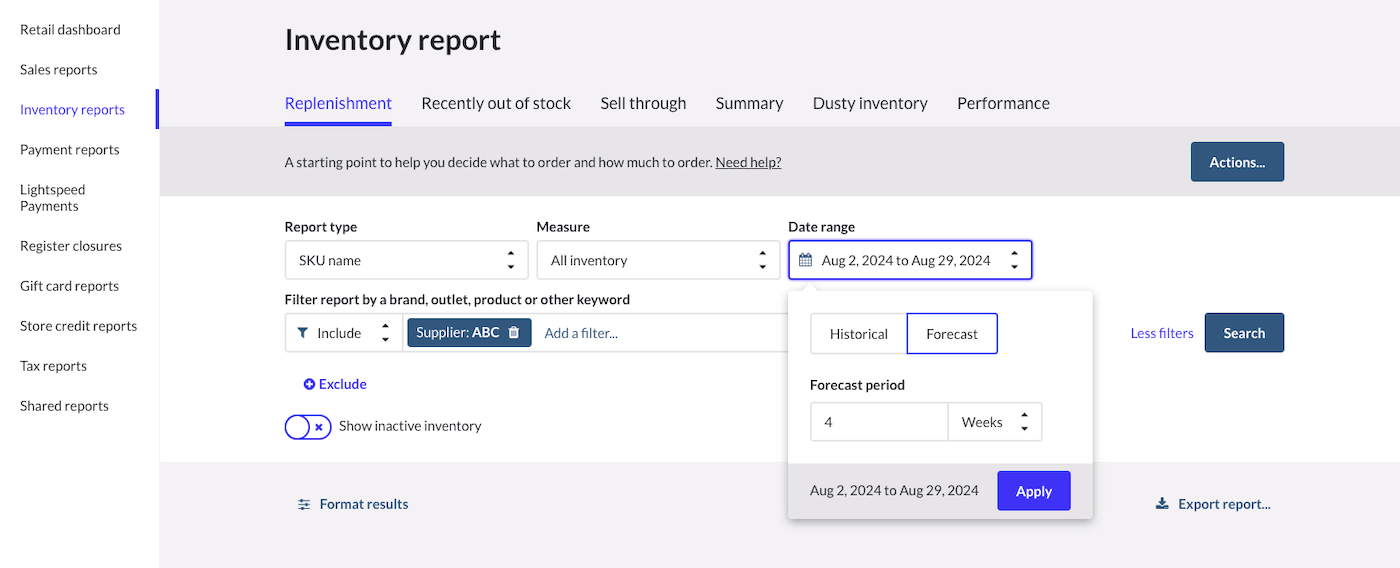

Advanced tools and analytics help improve forecasting. Lightspeed Insights, for example, can forecast demand and suggest order quantities based on your historical data.

But even the best systems cannot fully eliminate all unpredictability, making demand forecasting a constant challenge you need to keep on top of.

Supply chain disruptions

Supply chain uncertainties—such as shipping delays, supplier issues or global crises—can wreak havoc on inventory management. These disruptions make it difficult to maintain optimal stock levels and can lead to costly delays or gaps in product availability, even when your forecasting was otherwise impeccable.

Managing inventory effectively under these conditions requires flexibility, strong supplier relationships and contingency planning to ensure that stock can be replenished or adjusted without significantly disrupting business operations.

Overstocking and stockouts

Balancing inventory levels to avoid both overstocking and stockouts is a key challenge. Overstocking ties up capital in unsold goods, increases holding costs, and may lead to spoilage or obsolescence.

On the other hand, stockouts result in missed sales opportunities, frustrated customers and damaged brand reputation.

Regularly struggling with either—or both—indicates to customers that you don’t know what they want. But even with a well-tuned forecasting and ordering system, sudden changes in customer preference can lead to overstocks and stockouts. Retailers without a plan to handle excess inventory will be stuck with products they can’t move, tying up cash flow. Retailers without a way to fill shelves will turn customers away.

Did you know? You can place special orders for customers using Lightspeed’s built-in purchase orders, helping you make the sale even if you’re out of stock.

Inventory visibility

Tracking and managing inventory across multiple locations can be a complex task, especially for businesses with numerous warehouses or retail outlets. Poor visibility into stock levels across different locations can lead to inefficiencies like duplicate orders or unfulfilled customer demands.

The lack of real-time, centralized data makes it harder to manage inventory effectively, especially when trying to optimize stock transfers between locations to meet varying demand levels.

Technology integration

Integrating inventory management software with other business systems, like accounting, CRM or ecommerce platforms, can pose significant challenges when you’re weighed down by legacy software or insufficient tools.

Poor integration leads to data silos, errors in stock counts, and a lack of real-time updates.

Lightspeed POS solves these issues seamlessly by offering smooth integration with a wide range of business systems. Our centralized platform allows real-time inventory tracking across multiple locations, syncing data automatically with other business tools to streamline operations without the complications typically associated with software integration.

Inventory management software

So inventory management is important—how do you switch away from spreadsheets and opaque operations?

That’s where inventory management software comes in.

Retail inventory management software helps automate tasks like inventory tracking, order processing and stock replenishment to reduce manual errors, improve accuracy and free up valuable time for other operational tasks. It also provides real-time insights into stock levels, sales trends and demand forecasts, enabling businesses to make data-driven decisions to optimize stock levels and reduce costs.

Lightspeed POS for retail inventory management

“[With Lightspeed,] we’ve grown the business 50% just [by] being able to track our inventory.” Becky Boileau, Marketing Manager, The Plus Factor

Lightspeed POS is a powerful tool for inventory management in retail, offering features specifically designed to streamline and enhance stock control—features like:

- Real-time inventory tracking: Lightspeed provides a live view of stock levels across multiple locations, ensuring accurate data and helping to prevent stockouts or overstocking

- Automated reorder recommendations: businesses can set reorder points so that the system automatically calculates ideal amounts for purchase orders when inventory reaches critical levels, eliminating the guesswork and reducing human error

- Bulk inventory management: Lightspeed allows users to manage large volumes of stock efficiently, with tools for batch processing, product categorization and bulk edits

- Seamless integration with sales and order management: Lightspeed connects inventory data directly with sales and order management systems, ensuring smooth operations and reducing errors across multiple platforms

- Product variants and bundles: retailers can easily manage product variants (like sizes or colors) and create bundles, offering more flexibility and control over stock

- Easy reporting and analytics: Lightspeed provides detailed, user-friendly reports and analytics that give businesses deeper insights into product performance and demand, enabling more informed decision-making

- Scalability: as your business grows, Lightspeed grows with you, offering scalability that adjusts to the needs of larger operations, multiple locations, and expanding inventory

“I will say pallets used to take us about three, 3.5 hours per pallet of labor hours for a staff to process. [With Lightspeed,] it’s down to about an hour and 15 minutes at this point. Two staff can knock it out in 40 minutes. It’s cut our time pretty much in half.”

Wendel Wray, Global Retail Manager, Lighthouse Immersive

Wrapping up

Effective inventory management is essential for maintaining business efficiency, controlling costs and ensuring customer satisfaction. The challenges of forecasting demand, navigating supply chain disruptions and maintaining visibility across multiple locations are best met with a little technological help.

Leveraging technology solutions like Lightspeed POS can help businesses automate and optimize their inventory processes. With features such as real-time inventory tracking, seamless integration with sales and order management, automated reordering and advanced reporting, Lightspeed POS ensures businesses can efficiently manage stock and scale as they grow.

Why not watch a demo and see for yourself?

Frequently asked question about inventory management

What is inventory visibility?

Inventory visibility refers to the ability to track and view stock levels in real time across all locations, whether in warehouses, stores or transit. It ensures businesses know exactly where their inventory is at any given time, improving accuracy, fulfillment speed and overall operational efficiency.

Why is inventory management important?

Inventory management is crucial for optimizing stock levels, reducing costs and meeting customer demand. It helps prevent overstocking and stockouts, improves cash flow and ensures smooth order fulfillment. Effective inventory management directly impacts profitability, customer satisfaction and the efficiency of business operations by ensuring you’re not overspending on stock or losing out on sales with empty shelves—in other words, inventory management helps you hit the sweet spot for optimal business.

How does inventory management work?

Inventory management involves tracking and controlling stock from procurement to sale. It ensures that businesses have the right amount of stock at the right time. This process includes:

- monitoring inventory levels

- reordering products as needed

- optimizing storage and fulfillment to avoid excess or shortages

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.