Excess inventory is a major concern for just about every retailer, and for good reason: it ties up cash and drives up storage costs.

These issues compound significantly if you’re a growing or highly established business. For retailers managing multiple locations or scaling operations, it’s an issue that needs addressing quickly.

Surplus stock doesn’t happen by accident. It can stem from inaccurate forecasts, shifting market trends or supply chain hiccups. Often, the causes overlap, making it essential to pinpoint the root of the problem before taking action.

The good news? Because it doesn’t happen by accident, you have control over your stock. You can manage excess inventory effectively with the right strategies and tools. From smarter planning to using technology for real-time tracking, there are practical ways to turn surplus into solutions.

- What is excess inventory?

- Causes of excess inventory

- The consequences of excess inventory

- Excess inventory management solutions

- How to get rid of excess inventory

- How to prevent excess inventory in the future

Grow your retail business.

Streamline inventory, suppliers, teams and stores with Lightspeed's all-in-one platform. From intuitive POS and stock management features to powerful reporting, Lightspeed gives you the tools you need to grow.

What is excess inventory?

Excess inventory is any stock that surpasses customer demand or sales projections. It’s the extra merchandise sitting on shelves or in storage, taking up space and resources without bringing in revenue. This often happens when purchasing plans or sales forecasts miss the mark, leaving you with more product than your customers want.

Too much inventory ties up cash that could be used elsewhere. It also raises storage costs—whether for warehouse space, utilities or the labor needed to manage it all. If left unchecked, surplus stock can becomedead stock, meaning it’s unsellable due to obsolescence, expiration or shifts in consumer trends.

The financial strain doesn’t stop there. Excess stock often results in markdowns or discounts, which eat into your profit margins. For perishable items or trend-driven products, the losses can be even greater when products expire or lose relevance. Addressing surplus inventory quickly and strategically is key to protecting cash flow and staying competitive.

Causes of excess inventory

Inaccurate demand forecasting

Getting demand forecasting wrong is one of the biggest reasons for excess inventory. Overestimating how much customers will buy often leads to overordering—products sit on shelves, tying up space and cash.

That’s why choosing the right demand forecasting method is key. When trends shift unexpectedly or forecasts miss the mark, especially without the help of real-time data, it’s easy to end up with more inventory than you need.

Supply chain disruptions

Supply chain issues can throw inventory planning off balance fast. Late shipments or supplier delays often cause businesses to overorder as a precaution, leading to unnecessary stock. Problems like inconsistent product quality or production slowdowns further disrupt inventory levels, leaving retailers with more goods than they expected—sometimes all at once.

Seasonal products

Seasonal items are tricky to manage. Products tied to holidays or specific times of the year, like winter coats or summer decor, require precise planning. Leftover inventory after the season ends risks sitting in storage for months, or worse, becoming unsellable by the next cycle if it’s outdated or irrelevant.

Bulk buying and discounts

Buying in bulk to save money sounds great—until the inventory doesn’t sell as planned. Supplier discounts often encourage larger purchases, but if demand is overestimated, that extra stock can quickly become excess. Bulk buying might reduce costs upfront, but it can lead to storage headaches and cash flow problems when products don’t move.

Slow sales

Even with accurate planning, not every product performs as expected.Slow-moving items, whether due to changing trends or lack of customer interest, can pile up and become dead stock. New product launches that fail to gain traction or competitors offering better alternatives can also leave inventory stuck on shelves longer than anticipated.

Knowing why excess inventory happens is key to tackling it head-on. Each cause presents an opportunity to adjust processes, reduce waste and keep stock levels lean and profitable.

The consequences of excess inventory

Increased holding costs

One of the biggest challenges of inventory management is surplus. It’s not just inconvenient—it’s expensive. Warehousing fees, utilities and insurance costs climb fast when unused stock takes up space. On top of that, managing, organizing and tracking extra inventory adds labor costs, eating into profit margins even further.

Tied-up capital

Excess inventory ties up cash that could be better spent elsewhere. The money locked in unsold stock could fund new product launches, marketing efforts or operational upgrades. Instead, it sits idle, limiting your ability to invest in growth or react to new opportunities.

Product obsolescence

Some products lose value faster than you’d expect. Perishable goods like food or beauty items expire, while tech products quickly become outdated as newer models hit the market. Even durable goods can fall victim to shifting consumer trends, turning them into dead stock with no chance of a return.

Impact on cash flow

Carrying too much inventory puts pressure on cash flow. Everyday expenses like payroll or supplier payments become harder to manage when working capital is tied up in stock that isn’t selling. This often forces businesses to borrow, adding interest fees that increase financial strain.

Excess inventory management solutions

Accurate demand forecasting

When choosing inventory management software, it’s important to choose a system that has strong forecasting capabilities. Forecasting is the backbone of managing inventory effectively. Relying on historical sales data, seasonal patterns and market trends helps you predict customer demand with greater accuracy. When done right, it reduces the risk of overstocking and ensures you’re only ordering what’s necessary for your business to thrive.

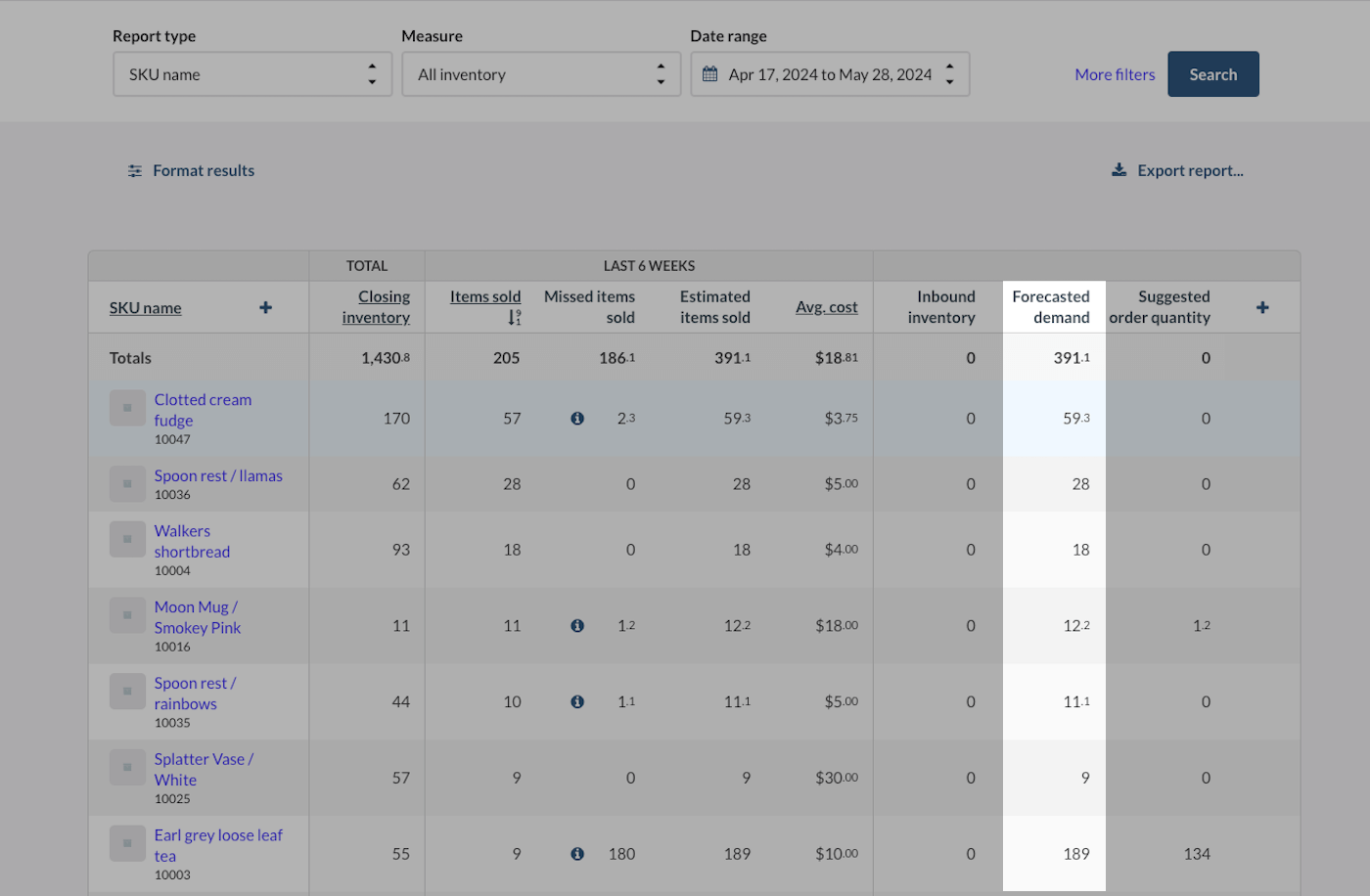

One of the ways that you accurately forecast inventory demand is through technology. Lightspeed Retail, for example, offers inventory insights and makes recommendations for your order quantities. This helps you avoid issues like overstock and enables you to invest in products that fly off the shelves.

Inventory optimization tools

The right tools make a big difference in staying on top of inventory.Inventory management systems track stock in real time, send low-stock alerts and provide detailed sales insights. With this data, you can adjust stock levels, reorder strategically and avoid letting surplus inventory stack up.

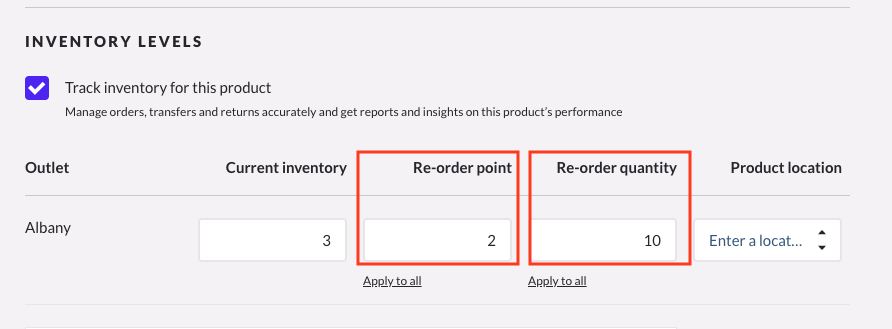

Pro tip: Set reorder points and thresholds based on sales trends to prevent overstocking and stockouts, keeping your inventory balanced and efficient. Doing this is super simple with Lightspeed.

Just enter a re-order point, the minimum current inventory quantity at which the product is recommended to be reordered when creating a purchase order.

Lean inventory management

Lean practices, likeJust-in-Time (JIT) inventory, are designed to keep stock levels proportional to immediate needs. JIT ensures products arrive exactly when needed—no earlier, no later. It’s a simple way to free up storage, cut carrying costs and stop surplus before it starts.

Supplier collaboration

Working closely with suppliers opens up opportunities for smarter inventory decisions. Maintaining clear communication allows you to adjust order quantities quickly when demand shifts. Some suppliers even offer consignment options, so you can stock products without committing to upfront purchases—lowering financial risks.

Regular inventory audits

Audits help uncover slow-moving or outdated stock before it becomes a bigger problem.Regular inventory audits (aka physical inventory counts) keep your inventory accurate and give you the chance to take action on surplus early. When you stay on top of audits, you’ll also improve forecasting and make better purchasing decisions moving forward.

Again—technology is your friend here. When conducting inventory counts, opt to use automated tools like barcode scanners so you and your team can reduce errors and complete counts faster. The health and beauty retailer Neal’s Yard did just that through the Scanner by Lightspeed app.

Managing excess inventory isn’t about luck—it’s about having the right processes in place. Combining technology, lean practices and strong supplier relationships helps keep stock levels balanced while protecting your bottom line.

How to get rid of excess inventory

Discounts and promotions

Discounts are one of the quickest ways to move excess inventory. Clearance sales, flash sales and targeted discounts grab attention and create urgency for customers to act. Promote these deals across all your marketing channels to reach more shoppers and turn slow-moving stock into cash.

Bundling products

Bundling is another great way to clear out excess stock while boosting perceived value. Pair less popular items with bestsellers and offer the bundle at a special price. For example, combine a slow-moving product with a high-demand item that complements it. Customers get a deal, and you move inventory faster.

Liquidation

Liquidating unsold stock in bulk is an efficient way to recover costs and free up space. Working with liquidation companies or wholesalers lets you offload large quantities quickly. While the profit margins are lower, liquidation helps clear out products that might otherwise sit in storage indefinitely.

Donations

Donating excess stock to charities or non-profits can be a smart move. It clears storage space, often comes with tax benefits and enhances your brand’s reputation. Choose organizations that align with your values to make the donation both meaningful and impactful.

Online marketplaces

Selling surplus inventory on secondary marketplaces is another effective option. These platforms connect you with deal-hunters who are specifically looking for discounted products. It’s a good way to reach new audiences and sell items that no longer fit into your primary sales strategy.

Each of these approaches helps tackle excess inventory in a different way. The key is to take action quickly—whether through discounts, donations or liquidation—so your stock doesn’t sit idle and drain resources.

How to prevent excess inventory in the future

Improve forecasting techniques

Forecasting is the backbone of managing inventory effectively. Advanced tools like data analytics and AI can help you track historical sales, seasonal trends and shifts in customer demand. With predictive analytics, you can make smarter decisions and avoid stocking more than you’ll sell.

Smarter purchasing decisions

Take a closer look at your purchasing habits. Overordering, especially for seasonal or slow-moving items, often stems from chasing bulk discounts or supplier deals. Instead, focus on buying only what aligns with realistic sales projections. Regularly check purchase orders to ensure they support healthy inventory turnover.

Better inventory turnover ratios

A steady flow of inventory keeps operations running smoothly and prevents stock from piling up. Monitor your inventory turnover ratio—how often stock is sold and replaced—and make adjustments as needed. Faster turnover not only reduces the risk of dead stock but also keeps cash available for other priorities.

Diversify marketing channels

Selling through multiple channels is an effective way to move inventory before it becomes excess. Expand your reach by using online marketplaces, social media or direct-to-consumer ecommerce platforms. You can also target different customer groups with personalized promotions to improve sales velocity and balance stock levels.

Adjust safety stock levels

Safety stock is there to protect against unexpected demand or delays—but too much can quickly become a problem. Revisit your safety stock quantities by factoring in lead times, supplier reliability and current market trends. Fine-tuning these levels helps you avoid tying up cash and storage space in unnecessary inventory.

Preventing excess inventory isn’t about one big change—it’s about refining your processes. From smarter forecasting to diversified sales strategies, each adjustment contributes to a more balanced and efficient inventory system.

Bottom Line

Excess inventory isn’t just about running out of space—it’s a drain on cash flow, profits and day-to-day operations. Fixing it means taking a clear, strategic approach. That includes better forecasting, leaner inventory practices and building strong supplier relationships. When you tackle the root causes and put the right systems in place, excess stock stops being a problem and starts becoming an opportunity.

Staying ahead of excess inventory means managing it proactively. Real-time tracking and data-driven forecasting are powerful tools to keep stock levels in check. They don’t just make your processes more efficient—they help you make smarter decisions that drive growth and protect your bottom line.

Talk to an expert to see how smarter inventory tools can take your business to the next level.

FAQs

Is excess inventory good or bad?

Excess inventory is usually bad for your business—it ties up cash, drives up storage costs, and risks products becoming obsolete. Still, there are rare moments when having extra stock can help, like during peak seasons or unexpected supply chain delays. The trick is finding the right balance—too much inventory drains resources, but too little means lost sales.

How to identify excess inventory?

You can spot excess inventory by looking atinventory turnover ratios, which show how often stock is sold and replenished over time. Pay attention to slow-moving products, outdated items, or stock levels that don’t align with sales forecasts. Regular audits and using real-time tracking tools make it easier to flag and fix surplus before it becomes a bigger problem.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.