Consignment inventory is a supply chain model that enables retailers and suppliers to build flexible, mutually beneficial partnerships. Whether it’s high-end jewelry, seasonal decor or artisan goods, consignment inventory agreements can be a win-win for both parties.

However, like anything in business, effective consignment inventory management requires careful planning and execution to succeed. From crafting an airtight contract to leveraging technology for tracking and reporting, keep reading to learn how to implement and navigate the nuances of consignment inventory.

- What is consignment inventory?

- How consignment inventory works

- Advantages of consignment inventory

- Disadvantages of consignment inventory

- How to manage consignment inventory

- Consignment inventory best practices

Managing Inventory Across Multiple Outlets: A Complete Guide

Dive into the essential stock management best practices every multi-store or multi-channel retailer should know in this free guide.

What is consignment inventory?

Consignment inventory is a supply chain strategy or business agreement in which the consignor (e.g. wholesaler, supplier, manufacturer) gives the goods to a consignee (e.g. the retailer) to sell. The consignor still owns the products and the consignee will only pay for them once they’ve been sold.

For example, a supplier might strike a deal with a big-box retail store to sell its outdoor Christmas lights and decorations between September and December. The store will only pay for the goods that sell, and the rest can be returned to the supplier after the specified time period.

Your local cafe that also sells hand-crafted cafetières or organic lip balms at the cash register may be selling those goods on consignment. A boutique gift shop in a popular tourist destination may sell a mix of their own branded goods, goods they’ve purchased outright from suppliers, as well as curated work from local artists that are supplied on consignment.

Because the retailer only pays the supplier after a product is sold, the inventory consignment model enables retailers to maintain a more flexible cash flow, freeing up resources for other expenses. Done right, a consignment inventory arrangement is a win-win situation for both parties.

Popular products sold through the consignment model include (but are not limited to) apparel and footwear, jewelry and accessories, art, toys and seasonal products (e.g. holiday decorations).

How consignment inventory works

Here’s how a typical consignment inventory process works, from the initial agreement to managing sales and returns. Each step helps to ensure a smooth process and amiable partnership between the supplier and retailer.

- “The Pitch”: The first step in the process typically begins with a supplier (consigner) approaching a retailer (consignee) to propose a consignment inventory agreement.

- Negotiating terms: Both parties negotiate the terms of the agreement and these are formalized in a written contract, ensuring clarity on roles, responsibilities and ownership of the goods—for example, who’s responsible for lost or damaged products. Terms may include (but are not limited to):

- duration of the consignment period

- cost of goods

- proceeds split

- shipping fees

- deposits and/or commissions

- inventory management requirements

- returns handling requirements

- Inventory delivery: Once the agreement is in place, the supplier delivers the products to the retailer. Ownership of the goods still belongs to the supplier, even though they are on the retailer’s shelves.

- Display and sales: The retailer displays the products and sells them to customers as usual. The supplier may offer guidance on merchandising or provide promotional materials to help increase sales.

- Tracking and reporting sales: Throughout the consignment period, the retailer tracks sales and provides regular reports to the supplier. This transparency ensures both parties know which items have sold and which are still in stock.

- Payment for sold goods: The retailer only pays the supplier for items that have sold, keeping a pre-agreed upon portion of each sale as commission. This payment is typically made at regular intervals—like monthly or quarterly, or once sales have reached a certain threshold—depending on the terms.

- Return or restock unsold items: At the end of the consignment period, unsold items can either be returned to the supplier or restocked based on demand and new terms. In some cases, the retailer may have the option to buy-out unsold inventory at the end of the consignment period, sometimes at a more favorable split. However, buy-out options are usually negotiated in advance and may not be offered by all suppliers.

Advantages of consignment inventory

Inventory management challenges can cause many headaches, and that’s why consignment inventory can offer significant advantages for suppliers (consignors) and retailers (consignees) alike. Let’s break them down below.

Advantages for suppliers:

- Increase brand/product visibility. Consignment inventory gives suppliers the ability to reach new audiences by selling their products through retail stores, allowing them to generate revenue without their own employees or retail space.

- Testing in new markets. Consignment inventory enables suppliers to test new products in new markets, which can help them evaluate the product’s performance based on actual sales numbers. Insights gained from market testing can help suppliers/vendors tweak their product launch strategy for better success.

- Reduced warehousing costs. For suppliers who need to store large quantities of stock, one of the benefits of consignment inventory includes reducing carrying costs by placing goods with retail partners until they sell.

Advantages for retailers:

- Low financial risk. Because retailers don’t pay for products until they’re sold, they don’t need to worry about overstocking, losing money on unsold inventory or tying up too much capital in inventory.

- More product diversity, higher sales potential. With inventory consignment, retailers can diversify their offering, thereby increasing sales opportunities. Because the financial risk is so low, even retailers with limited cash flow can take on new products.

- Fewer storage needs. Because they can return whatever doesn’t sell, retailers don’t need to make special storage arrangements for excess stock at the end of the consignment period. Consignment stock can be replenished as needed, based on customer demand.

Disadvantages of consignment inventory

Consignment inventory isn’t always an ideal arrangement for suppliers or retailers. Let’s dive into some of the potential downsides of this supply chain strategy.

Disadvantages for suppliers:

- Higher upfront costs. Consignors carry the cost of producing the goods, without a guaranteed payoff. Besides potential revenue losses if products don’t sell, there are a variety of expenses they could find themselves responsible for, such as shipping costs (or shipping costs for returns by consumers) or costs associated with damaged items.

- Unpredictable cash flow. Suppliers have to wait to receive payment for sold goods, which can sometimes make cash flow feel more like a cash trickle. They may also receive less money from retailers than expected during a particular accounting period.

- Dependent on retailers to sell goods. Suppliers have to trust that their retail partners are going to make a strong effort to showcase and sell their products. Because retailers assume little financial risk on the consignment model, suppliers can’t be 100% sure that the retailer is making every effort to sell their products in good faith.

Disadvantages for retailers:

- Responsibility for damaged or stolen goods. Retailers are usually on the hook for paying suppliers for stolen or damaged inventory—unless it arrived that way—even if it doesn’t sell. It’s a good idea to insure consignment inventory, especially high-value items. It isn’t your property—so if something happens to it, you’ll want to be able to recover the value of it.

- Inventory management complexity. Consignment inventory can sometimes make stock management more difficult. Consigned goods should be tracked separately from non-consignment items. And since they technically don’t come with any upfront supply costs, accurately tracking your margins and profits could be trickier, depending on your inventory management system.

- Additional costs. Depending on the arrangement, retailers may be responsible for additional costs, such as shipping or warehousing costs, insurance, etc.

How to manage consignment inventory

Effectively managing consignment inventory requires a proactive approach to ensure smooth operations and mutual success. For retailers that sell a combination of consigned and non-consigned goods, managing inventory can be a complex task.

Here’s how retailers can effectively manage consignment stock:

1. Use inventory management software

That’s why choosing the best inventory management software can be a real game changer. These systems let you perpetually (and automatically) monitor stock levels, sales and replenishment needs in real-time.

2. Monitor sales trends regularly

Analyze sales data to identify which consignment items are performing well and which aren’t. Use this information to optimize stock levels and focus on high-demand products.

A retail POS with robust data and reporting will help you quickly identify what you’ve sold and what you owe your consignor so you can make timely, accurate payouts—backed up by sales and inventory data—and maintain a harmonious partnership.

In Lightspeed Retail, you can easily track metrics like number of units sold, return count and percentage, last date sold and much more by adding an appropriate tag (e.g. “consignment”) to consignment items and then filtering your sales report by that tag.

3. Conduct routine inventory audits

Schedule periodic checks to verify your physical stock matches inventory numbers in your retail POS. This helps maintain transparency for stakeholders and is crucial for accurate consignment management.

4. Automate inventory tracking and purchase orders

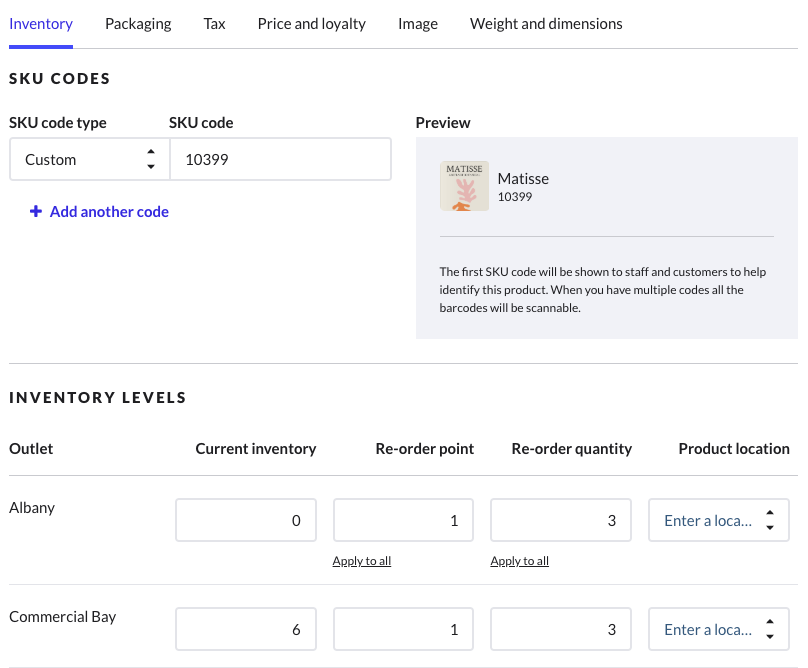

Define thresholds for reordering or restocking consignment items. Setting up reorder points and restock levels will allow you to automatically populate purchase orders and save a lot of time on manually tracking consignment inventory stock levels.

For example, let’s say you sell a variety of art prints on consignment. And let’s say you want to have at least three of any given print in stock at each of your stores. In Lightspeed Retail, you’d simply enter a reorder point (the lowest number of units you can have in stock before you have to place a new order), and then a restock level (how many items you want to order when inventory hits this trigger number).

5. Streamline communication between parties

Establish clear communication channels between you and your consignor. Share regular updates about stock movement, sales performance and any issues to prevent misunderstandings and build trust. With these tools and features, retailers can manage consignment inventory efficiently, leading to improved profitability and stronger partnerships.

Consignment inventory best practices

So, how can you make consignment inventory work in your store? While every arrangement will vary, strong consignment agreements typically take place when you implement the following best practices:

- Have a solid contract. The contract is the single most important part of a successful consignment arrangement. It should be comprehensive and meticulous, spelling out all the terms of the agreement. Don’t leave anything open to interpretation. Both the supplier and the retailer should understand the terms of the agreement, including shipping and returns responsibilities, when payments will be made and who is responsible for damaged or lost products.

- Leverage technology. The best way to manage consignment and other inventory is to digitize your accounting and inventory systems. Instead of using spreadsheets or paper-based systems, adopt a cloud-based inventory management software that streamlines data entry, tracking and reporting.

- Communicate. Communication between the supplier and the retailer is key throughout the relationship. Retailers should keep very detailed inventory and sales records and update the consigner regularly. When issues arise, both parties should look for a mutually agreeable solution.

The bottom line

Consignment inventory can be a great strategy for retailers and suppliers looking to share risks and rewards. Retailers can expand their product offerings without heavy upfront investment, while suppliers can achieve greater market visibility and reach.

But, as with anything in business, managing consignment inventory is not without its challenges— including potential cash flow issues for suppliers and added inventory management complexities for retailers.

Robust inventory management software like Lightspeed Retail can help streamline and simplify these complexities. Want to see how? Talk to a POS expert today.

By crafting clear agreements, leveraging technology and maintaining open communication, businesses can make the most of consignment arrangements, build strong partnerships, increase sales and share success.

FAQs

What integrations does Lightspeed POS offer for inventory management?

Lightspeed POS integrates with leading inventory management tools, including Brightpearl, Inventory Planner, NetSuite, Local Inventory on Google, etc., to streamline tracking, reporting and reordering processes.

Lightspeed also seamlessly integrates with NuORDER, a wholesale B2B platform, to allow retailers to manage suppliers/vendors, upload product images and descriptions instantly to their POS, discover new products and create purchase orders all in one place.

How does Lightspeed POS improve data accuracy in inventory management?

Lightspeed POS enables retailers to automate inventory tracking processes and provides real-time updates, significantly reducing or even eliminating manual errors. Its robust reporting tools ensure your inventory and sales data align seamlessly, saving you time on physical inventory counts and reconciliation.

Can Lightspeed POS handle multi-location inventory management?

Yes, Lightspeed POS offers powerful multi-location inventory management, allowing you to track stock levels, transfers and sales across multiple stores and sales channels from a single platform.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.