Countless hours counting stock, struggling with inaccurate spreadsheets, constantly worrying about stockouts… at one point or another, nearly every retailer has been there. Manual inventory management is a major drain on your time and resources.

Fortunately, there’s a better way. Automated inventory management empowers retailers to optimize their stock control, improve efficiency and boost their bottom line.

In this blog post, we’ll explore:

- What automated inventory management is

- Types of automated inventory management

- Why automated inventory management is important

- Benefits of automated inventory management

- Best practices for automated inventory management

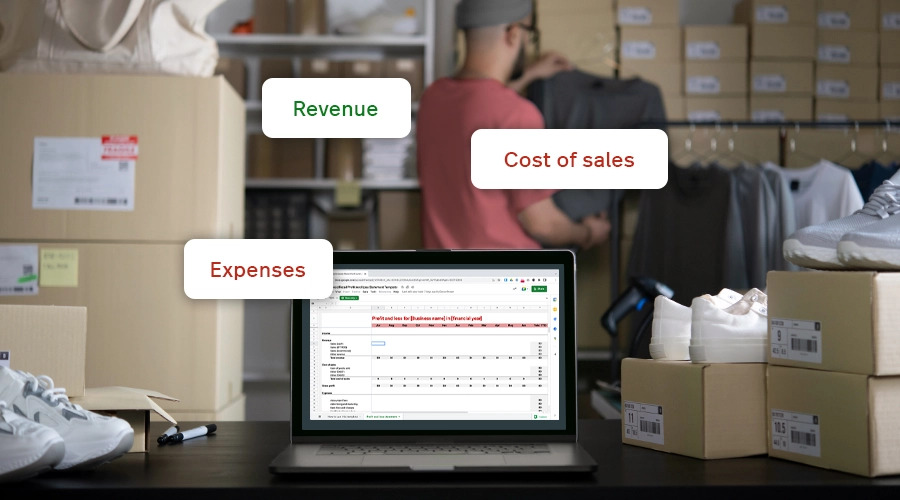

Profit and Loss Template

Examine the financial health of your business by highlighting exactly how much revenue is being generated versus what’s being spent.

What is automated inventory management?

Automated inventory management is when you use software and technology to track and monitor stock levels. Instead of manual counts and spreadsheets, an automated (or semi-automated—more on that later) system that tracks every item in real-time, anticipates your needs and helps you make informed decisions.

Automated inventory management takes the guesswork out of stocking your business. For retailers, that means potentially increased efficiency, reduced errors and better control over your stock. Automated inventory management helps reduce stockouts, overstocking and the headaches of manual inventory management. With real-time data at your fingertips, you can optimize ordering, minimize waste and ultimately, improve your bottom line.

Automated inventory management relies on a combination of tools working together seamlessly.

Point of sale and inventory management software

Software systems act as the brain, providing a centralized hub to monitor stock levels. Retail POS systems record each sale, return and new stock order, automatically updating inventory counts in real-time.

This data feeds into the inventory management software, which tracks stock levels, predicts demand and triggers purchase orders when necessary while enabling managers to make informed decisions.

Some systems can also forecast demand based on historical data, allowing retailers to optimize inventory and reduce holding costs.

Scanners and tags

Barcode scanners and RFID tags allow for instant updates as items move in and out of your warehouse and store locations.

Here’s how that feeds into automated inventory management:

- When a new product arrives at a warehouse, it’s scanned to confirm arrival, updating the inventory system with its exact location and quantity

- As it’s stored in the warehouse, another scan logs its placement, making it easy to locate later

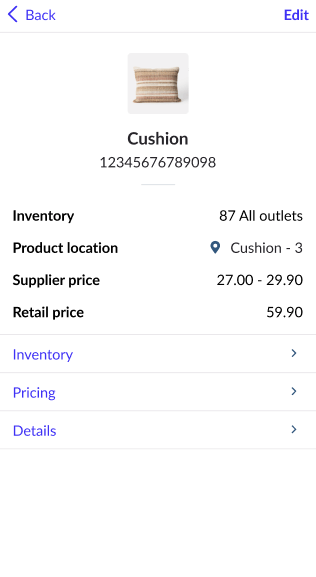

Product location information as seen with Lightspeed Scanner

Product location information as seen with Lightspeed Scanner

- The product is transferred to a store. It’s scanned again upon departure and then once more upon arrival at the store, keeping inventory levels updated at each location

- When the product is sold, the POS system scans it at checkout, automatically adjusting inventory to reflect the sale

Internet of things (IoT) devices

For extra advanced automated inventory management, IoT devices, like smart shelves, can even track inventory without any human intervention, automatically sending alerts when stock is low

For example, with smart shelves, sensors continuously monitor stock levels as products are removed. From there, the shelves send automatic updates to the inventory management system. When inventory drops below a set threshold, smart shelves can trigger low-stock alerts or even reorder requests, ensuring that stock levels are consistently maintained.

Types of automated inventory management

Fully automated inventory management

Fully automated systems utilize technology to manage nearly every aspect of inventory control.

This includes:

- Real-time tracking of stock levels using devices like barcode scanners, RFID tags and IoT devices

- Automatic reordering of products based on predefined rules

- Integration with sales channels and accounting systems for automatic data sync

Automated inventory management systems minimize manual intervention and provide a comprehensive view of inventory across all locations and channels.

While offering significant efficiency gains and scalability over manual inventory management, fully automated systems typically require a larger upfront investment and may require ongoing technical support. They can also be opaque, and may fall out of line with sudden changes in the market environment without manual intervention.

Semi-automated inventory management

Compared to fully automated inventory management, semi-automated systems combine technology with some manual processes. This approach often involves using software to track inventory levels and generate reports, while tasks like stocktaking and ordering may still involve some manual effort—though typically greatly reduced when compared to manually managing inventory.

Semi-automated inventory management typically costs much less than a fully automated system, and can be less time intensive to set up. A semi-automated inventory flow could look like this:

- A retailer goes to make a new purchase order to restock their store. Their POS system, having tracked sales data, makes recommendations on what products should be ordered and in what quantity

- The product arrives at a warehouse. It is scanned by an employee, automatically updating the inventory management system with the new stock level

- When the product arrives at a store, it is scanned, automatically updating the POS data—it is removed from the warehouse inventory and added to the store’s stock

- When the product sells, data on how fast it sold, remaining stock level and other information like COGS is recorded in the POS to refine recommendations

Why automated inventory management is important

Automated inventory management is more than just a technological upgrade; it’s a crucial step towards optimizing your business operations and ensuring long-term success.

Here’s why.

Efficiency and accuracy

Manual inventory management is time-consuming and prone to human error. This can lead to stockouts, overstocking, inaccurate financial records and ultimately lost revenue and frustrated customers.

Automation streamlines the entire process, from tracking stock levels to reordering products. Tools like barcode scanners, RFID tags and IoT sensors provide real-time data, cutting down on tedious manual counts and reducing the risk of inaccuracies. This ensures you always have an accurate picture of your inventory, allowing you to respond quickly to market demands and customer needs.

Cost-effectiveness

Automation can lead to significant cost savings. By minimizing errors and optimizing inventory levels, retailers can reduce labor costs associated with manual data entry and stock taking. This also helps minimize losses from overstocking or stockouts, both of which impact your bottom line.

Automated systems and the data they collect can even identify slow-moving items, helping you make informed decisions about pricing and promotions to free up valuable warehouse space.

An example: dusty inventory with Lightspeed Insights

Dusty inventory—inventory that hasn’t moved in a while—clogs up your shelves and bogs down your business. Problem is, unless you’re doing weekly or monthly manual full counts, you might not notice what isn’t selling.

A system like Lightspeed tracks your sales data and your lack-of sales data, automatically identifying problem products to be dealt with. With that information easily on hand, you can focus on how you’re going to get it out the door, not on finding it in the first place.

Scalability

As your business grows, managing inventory manually becomes increasingly complex. Automation provides the infrastructure to scale your operations smoothly.

Whether you’re expanding your product lines, adding new sales channels, or increasing order volumes, this scalability ensures that inventory management remains a strength, not a bottleneck, as your business evolves.

Benefits of automated inventory management

Improved customer experience

Automated inventory management systems ensure you have the right amount of stock at the right time. By tracking sales and predicting demand, these systems can automatically reorder products—or automate recommendations on what you should order—preventing stockouts and ensuring customer satisfaction. That means no more disappointed customers or lost sales due to unavailable items.

Less miscalculations

Automated inventory systems significantly reduce human error by tracking stock in real-time. This eliminates manual counting and data entry, leading to more accurate inventory records and fewer discrepancies.

Imagine a busy clothing store during a weekend sale. A sales associate uses a barcode scanner to quickly ring up a customer’s purchases: a pair of jeans, a sweater and a scarf. The system instantly updates the inventory count for each item, ensuring accurate stock information even during the rush. Later that day, the system analyzes sales data and recognizes that the jeans are selling quickly. It automatically generates a suggested reorder amount for the store manager, ensuring they have enough jeans on hand to meet customer demand and avoid lost sales. This level of precision and efficiency would be difficult to achieve with manual inventory tracking, where human error in counting and recording sales is more likely to occur.

Time and labor savings

Inventory automation frees your staff from repetitive manual tasks like stocktaking and order processing. By automating these processes, your team can focus on more strategic activities like customer service and sales, leading to increased efficiency and a more engaged workforce.

Best practices for automated inventory management

Automated inventory management cuts down on work—but make sure you set your business up for success to get the most out of it.

Choose the right system

Select an automated inventory management system that aligns with your business needs and integrates well with your existing POS and other software—or, ideally, is an all-in-one system with POS and inventory management in one place.

To make the most of automation, evaluate potential systems with these steps:

- Identify your business needs: determine the specific requirements of your business, including size, product variety, and number of locations. Consider factors like multi-location management, demand forecasting and ease of use

- Check for real-time tracking: choose a system that offers real-time inventory tracking, essential for businesses needing up-to-the-minute stock information across multiple locations. Lightspeed POS, for example, updates stock levels instantly, preventing stockouts and overstocking

- Analyze reporting and insights: select software with robust reporting capabilities. Systems like Lightspeed offer in-depth sales and inventory reports, helping you make data-driven decisions on restocking, seasonal demand and product performance

- Review product management features: if you manage a diverse product line, ensure the system supports custom product categories, variants and bulk imports

- Evaluate scalability: choose a cloud-based, scalable solution that can grow with your business

Prioritize data accuracy

Ensure the data you input into the system is accurate and up-to-date. Regularly audit your inventory to maintain data integrity and optimize system performance.

While your automated system will handle most of the heavy lifting, periodic reviews are essential to ensure accuracy. Conduct a physical inventory count at least once a year—use barcode scanner tools to cut out human entry error. This allows you to identify any discrepancies between the system data and the actual physical inventory, allowing you to investigate and correct any inaccuracies.

Use real-time data for forecasting

Leverage the real-time data provided by your automated system to forecast demand, identify trends and make informed purchasing decisions.

For example, data collected by an automated inventory reporting system may reveal that a retailer’s sales of athletic wear have been steadily increasing over several months, with peak sales on weekends. This trend could suggest strong and growing customer interest in fitness-related products. The retailer could then decide to expand their inventory to include a new line of sports accessories, like yoga mats or resistance bands, anticipating that these items will appeal to their existing customer base and drive further sales.

Train your team effectively

Provide comprehensive training to your employees on how to use the new system. Encourage them to embrace the technology and understand its benefits to maximize efficiency and accuracy.

To successfully onboard your team to a new automated inventory management system:

- Start with the why: clearly explain the reasons for implementing the new system and how it will benefit both the business and the employees themselves. Highlight time savings, reduced errors, and improved efficiency

- Demonstrate real-life scenarios: use hands-on examples, like how to check stock levels or process a product transfer, to illustrate how the system fits into their daily tasks

- Emphasize data entry accuracy: explain the importance of accurate data entry and guide staff on recording inventory transactions, such as receiving new stock or logging returns, to prevent system discrepancies

- Teach reporting features: show team members how to generate simple reports on stock movement or sales trends. This gives them a better understanding of how their work influences inventory decisions

- Set up regular refreshers: schedule follow-up sessions to review system updates, answer questions, and reinforce correct usage, ensuring continuous improvement and familiarity with the system

- Encourage feedback: create a culture of open communication where staff feel comfortable sharing feedback and suggestions for improvement. This will help identify any areas where further training or system adjustments may be needed

Speed up inventory management with automation

Automated inventory management offers a compelling array of benefits. It increases accuracy in stock records, improves efficiency by automating tasks, allows for seamless scalability as your business grows and can lead to significant cost savings.

Take a close look at your current inventory processes and consider how automation can enhance your operations and drive future growth—could your POS and inventory management system be better? Lightspeed might be what you’re looking for. Watch a demo and see what we’re all about.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.