What are stockouts and why are they the bane of every retailer’s existence? These empty-shelf nightmares can lead to lost sales, frustrated customers and operational chaos.

You don’t need to fear a stockout—with the right planning, you can eliminate them almost entirely. In this blog, we’ll equip you with the knowledge and strategies to prevent stockouts, keep your inventory flowing smoothly and ensure your customers always find what they need:

- What is a stockout?

- 5 common causes of stockouts

- 17 ways to prevent stockouts

- Impact of poor stock management on business

- How Lightspeed can help

How to Manage Inventory Across Multiple Stores: A Complete Guide

Essential stock management best practices every multi-outlet retailer should know.

What is a stockout?

A stockout is an event in which a product is exhausted in inventory and, therefore, unavailable to fulfill an order.

Stockouts lead to immediate consequences:

- Lost revenue

- Damaged customer relationships

- Reputational damage

But the repercussions don’t stop there. In the long term, stockouts can also lead to:

- Decreased efficiency: staff may waste time searching for missing items or processing refunds

- Missed opportunities: your business loses the chance to upsell or cross-sell related products

- Increased costs: expedited shipping or rush orders to replenish stock can be expensive

5 common causes of stockouts

These stockout culprits can throw a wrench in your daily operations, leading to frustrated customers, lost sales and a whole lot of scrambling.

1. Inaccurate demand forecasting

This is like planning a picnic but forgetting to pack enough sandwiches. It’s when retailers misinterpret the data—or neglect to consult it at all—and end up with not enough stock to meet demand. Underestimating demand leaves your shelves bare and customers grumbling.

2. Supply chain snafus

Picture this: you’ve just placed an order for one of your best selling imports… and then a boat gets stuck in the Suez Canal. Now your order is going to be days, if not weeks, late.

Supply chain disruptions, from natural disasters to supplier delays, can throw your inventory into chaos. While they’re not all as dramatic as the Evergiven was, the more everyday hiccups can easily cause stockouts for businesses.

3. Manual inventory mishaps

Good old human error. We’ve all been there—mistyping a number, misplacing a spreadsheet, accidentally ordering a hundred pairs of shoes instead of ten. Relying wholly on manual inventory management is a minefield of potential mistakes, ripe for stockouts.

4. Inefficient warehouse operations

Imagine a warehouse where boxes are stacked haphazardly and items are mislabeled, making finding anything like navigating a maze blindfolded. Inefficient warehouse operations can lead to misplaced inventory, delays in fulfilling orders and ultimately stockouts.

5. Ignoring the data

Depending on the point of sale you’re using, you’ve likely got sales data, customer trends and market insights at your fingertips, but you’re too busy juggling spreadsheets to notice that demand for yoga pants is skyrocketing. Ignoring valuable data can lead to poor inventory decisions and, as a result, stockouts.

17 ways to prevent stockouts

Stockouts aren’t inevitable. With the right inventory management strategies, you can keep shelves stocked and business humming along smoothly.

1. Increase inventory accuracy

When it comes to data, garbage in means garbage out. Inaccurate inventory data is a recipe for disaster, leading to misinformed decisions and, you guessed it, stockouts.

To boost accuracy, ditch the dusty spreadsheets and embrace technology:

- Implement barcode scanners or RFID systems to track inventory in real-time

- Regularly audit your stock to catch any discrepancies and investigate the causes

- Use a cloud-based POS system with automated reporting capabilities

2. Reduce inventory

While it may seem counterintuitive, reducing inventory—or, at least, low-performing inventory—can actually help prevent stockouts.

Lower costs

By carrying less stock, you free up space, reduce holding costs and increase efficiency. This allows you to focus on your most popular and profitable items, ensuring you have adequate stock to meet demand.

More storage space

With slow-moving stock out of the way, you have more room for the big sellers and can hold more of it at once.

Increased efficiency

A streamlined inventory allows you to implement strategies like just-in-time inventory management to receive goods only when needed, minimizing excess stock and the risk of obsolescence.

3. Enforce regular cycle counting

Don’t wait until the annual inventory audit to discover discrepancies. Implement a regular cycle counting practice where small portions of inventory are counted daily or weekly. This helps identify and correct errors promptly, ensuring ongoing accuracy and preventing stockouts before they occur. Plus, it’s much less daunting than a massive, once-a-year stocktake.

You can speed up cycle counting (and reduce human entry error) by using a product scanning app like Lightspeed Scanner during counts.

4. Use automated inventory management software

Ditch the manual spreadsheets and embrace the power of automation. Inventory management software can track stock levels in real-time, automate reordering processes and provide valuable insights into sales trends and demand patterns. This helps you optimize stock levels and free up your time for more strategic tasks.

Lisa Bobb of Squash Blossom frees up time with automated inventory management from Lightspeed.

5. Integrate inventory platforms

If you’re selling across multiple channels, like a physical store, an online shop and various online marketplaces, it’s crucial to integrate your inventory platforms. When a product sells on one platform, the inventory count is automatically updated across all others, maintaining accurate stock information and a seamless customer experience. This ensures real-time visibility across all channels, preventing overselling and stockouts.

6. Identify stockout patterns

Don’t just react to stockouts—analyze them to see them coming. Identify patterns and trends to understand the root causes. Are certain products consistently running out of stock? Are stockouts more frequent during specific seasons or promotions? By understanding the why behind stockouts, you can implement targeted solutions and prevent future occurrences.

7. Keep safety stock

Expect the unexpected. Maintain a safety stock of critical items to act as a buffer against unforeseen demand spikes, supplier delays or other disruptions. This provides a cushion to prevent stockouts and ensure you can meet customer needs even when things don’t go as planned.

Can I keep safety stock while using just in time (JIT) inventory organization?

While JIT inventory aims to minimize stock on hand, safety stock seems to contradict that. However, they can work together:

- Strategic segmentation: use JIT for predictable, steady-demand items. Apply safety stock to those with fluctuating demand or unreliable supply chains

- Dynamic adjustment: regularly review and adjust safety stock levels based on real-time data and changing conditions

- Supplier collaboration: closely collaborate with suppliers to improve lead time reliability, reducing the need for large safety stock buffers

- Focus on high-impact items: prioritize safety stock for your most crucial or profitable products where a stockout would be most detrimental

8. Pay attention to customer trends

Your customers are a goldmine of information. Pay attention to their buying habits, preferences and feedback. Monitor social media, conduct surveys and analyze sales data to identify trends and anticipate future demand. This allows you to proactively adjust your inventory strategy and prevent stockouts by staying ahead of the curve.

9. Monitor the supply chain

Keep a close eye on your supply chain. Stay informed about potential disruptions, such as political instability, natural disasters or transportation issues. Also consider diversifying your supplier base to reduce reliance on a single source. By proactively monitoring the supply chain, you can anticipate potential delays and take steps to mitigate their impact on your inventory.

10. Develop strong relationships with suppliers

Your suppliers are your allies in the fight against stockouts—they want your shelves to be full of their products, after all. Build strong relationships based on open communication and mutual trust. Keep them informed about your inventory needs, especially during peak seasons or promotions. A reliable supplier can be invaluable in preventing stockouts and ensuring timely delivery of goods.

11. Use a vendor-managed inventory (VMI) system

You might be able to shift some of the responsibility of inventory management to your supplier. In a VMI system, the supplier monitors your stock levels and automatically replenishes inventory as needed. This reduces your workload, minimizes the risk of stockouts and strengthens your supplier relationship.

12. Implement consignment inventory

Reduce your inventory holding costs and the risk of stockouts by implementing consignment inventory.

In this model, you only pay for goods when they are sold, and the supplier—be it an individual or a business looking to liquidate inventory—retains ownership until that point. This is particularly beneficial for slow-moving or high-value items, as it reduces your financial risk and frees up capital.

13. Liquidate surplus stock

Don’t let excess inventory gather dust in your warehouse. Implement strategies to liquidate surplus stock, such as discounts, promotions or bundling offers. This frees up valuable space while reducing holding costs and minimizes the risk of obsolescence, allowing you to focus on stocking items that are in demand.

14. Keep customers informed

In the event of a stockout, be transparent with your customers and manage expectations. Keep them informed about the situation, provide estimated delivery times and offer alternative solutions. This helps maintain customer trust and minimize the negative impact on your business.

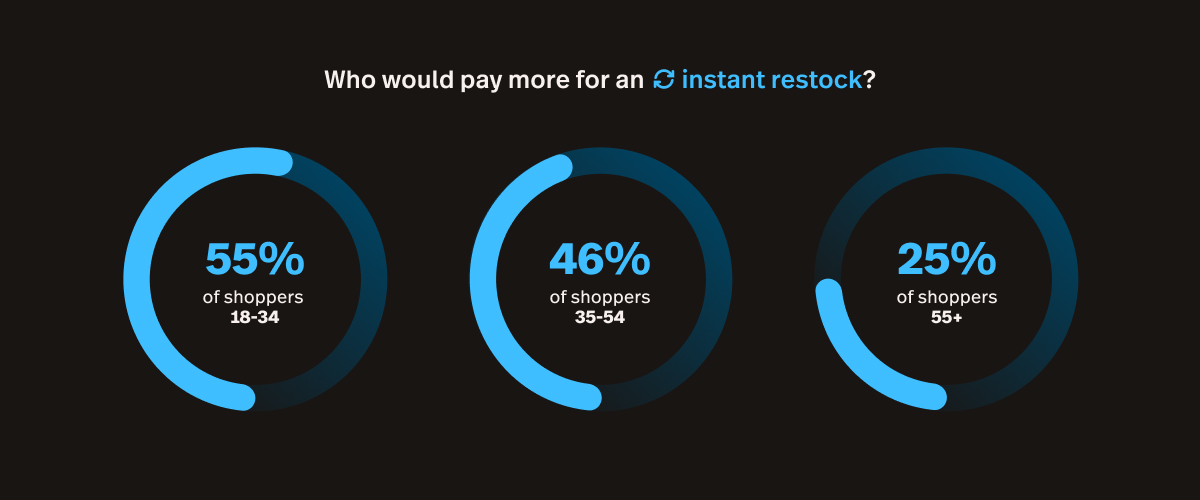

By the way, did you know Gen Z is more likely to pay extra for an instant restock when they’re confronted with a stockout?

15. Determine lead times

Understand the time it takes to receive goods from your suppliers. This includes order processing time, production time and shipping time. By accurately determining lead times, you can plan your orders effectively, ensuring timely replenishment and preventing stockouts.

16. Improve your forecasting

Accurate forecasting helps you optimize stock levels, ensuring you have enough inventory to meet demand without excessive overstocking.

Invest in tools and techniques to improve your demand forecasting capabilities. Utilize historical sales data, market trends and seasonality to predict future demand.

17. Utilize demand planning

Demand planning helps you anticipate future demand, optimize inventory levels, and prevent stockouts across your entire supply chain. This involves collaborating with various departments, such as sales, marketing and production, to create a comprehensive plan that aligns with your overall business goals.

Impact of poor stock management on business

Why is all of this so important? It’s just an empty shelf, right? Customers can always come back, or select another product…. Right?

If you’ve been in business long enough, you know that’s not true.

Decreased customer satisfaction

Imagine walking into your favorite store, ready to purchase that item you’ve been eyeing, only to find it’s out of stock. Frustrating, right?

Stockouts leave customers disappointed and empty-handed. This dissatisfaction can result in lost sales, negative reviews and decreased loyalty. Customers may turn to competitors who can consistently meet their needs, damaging your reputation and hindering long-term growth.

Lack of control over the supply chain

Poor stock management can feel like navigating a ship in a storm without a compass. You lack visibility into your inventory levels, leading to uncertainty about when to order, how much to order and where to store goods.

This lack of control can cause delays and disruptions, as well as increased costs throughout your supply chain, impacting your ability to fulfill orders efficiently and meet customer expectations.

Increased carrying costs

Overstocking might seem like a safe bet, but it can quickly become a financial burden—many retailers hold $1.43 in inventory for every $1 of sales. Excess inventory takes up valuable space, requires additional storage costs and increases the risk of obsolescence or damage. These carrying costs eat into your profit margins and tie up capital that could be used for other investments, hindering your business’s financial health.

Decreased profit margins

Poor stock management can be a silent profit killer. Stockouts lead to missed sales opportunities, while overstocking increases carrying costs. Both scenarios squeeze your profit margins, making it harder to achieve profitability and reinvest in your business. Inaccurate inventory data can also lead to incorrect pricing decisions, further eroding your profits.

Missed sales opportunities

Empty shelves equal missed opportunities. When customers can’t find what they need, they’re likely to walk away, taking their business elsewhere. Stockouts not only result in the loss of immediate sales but also potential future sales as customers may choose to shop with more reliable competitors. Missed sales opportunities limit your revenue potential and hinder growth.

Inefficient operations

Inefficient operations decrease productivity, increase labor costs and create a frustrating work environment for your employees. In particular, poor stock management can throw your operations into disarray. It leads to time wasted searching for misplaced items, processing returns or dealing with stock discrepancies.

This inefficiency can ripple through your entire business, causing stockouts by making inventory data—like sales and on-hand stock levels—opaque or outdated.

Poor cash flow management

Inventory ties up a significant amount of cash. Poor stock management can lead to an imbalance between cash inflow and outflow. Overstocking drains your cash reserves, while stockouts limit your ability to generate revenue. This imbalance can create cash flow problems, making it difficult to meet financial obligations.

Don’t get stuck with stockouts

Effectively managing your inventory is like walking a tightrope – it requires balance, precision and a good safety net.

By understanding the causes and consequences of stockouts, and implementing the strategies outlined in this blog post, you can optimize your inventory management, prevent those empty-shelf nightmares and keep your customers happy.

How does Lightspeed’s inventory management integration help?

Hey—nice to meet you. We’re Lightspeed, a retail point of sale and payments platform designed to help businesses get to the next level. Click here to watch a demo and see what we’re all about.

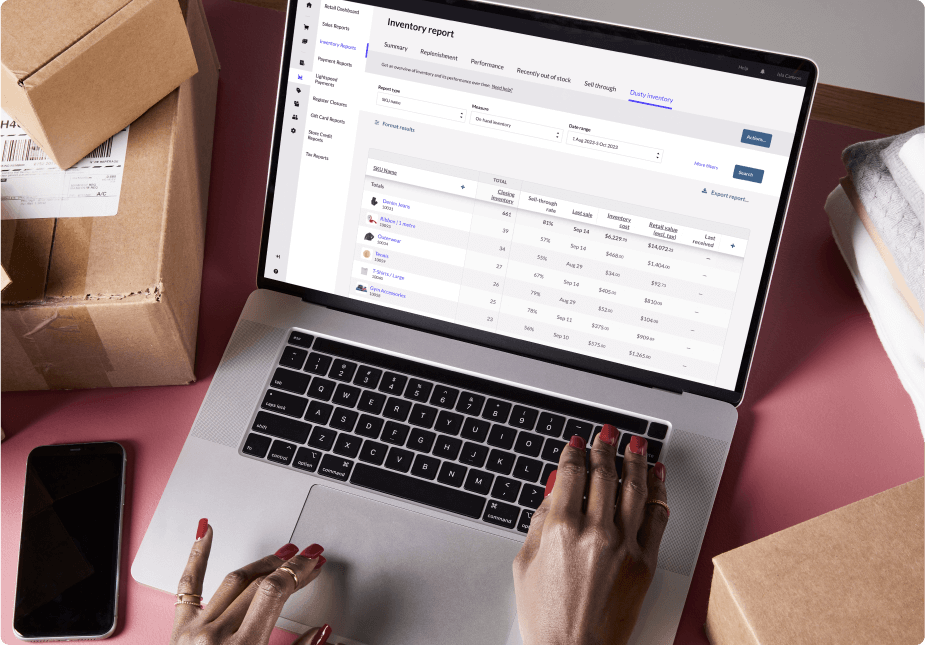

Lightspeed POS offers a range of features designed to streamline inventory management and help businesses avoid stockouts, providing a competitive edge. Our POS enables real-time inventory tracking across multiple locations, giving businesses an instant view of stock levels and movement.

With automated stock level updates, Lightspeed reduces human errors and frees up time for other tasks. This ensures that businesses can monitor inventory consistently, making it easier to prevent stockouts by identifying fast-selling products and placing timely reorders.

Data-driven insights are another standout feature of Lightspeed. Our Insights module provides comprehensive reports on inventory turnover, sales trends and seasonal patterns, allowing businesses to make informed purchasing decisions based on past performance. This feature helps retailers optimize their inventory mix, focusing on high-demand products while avoiding overstocking slower-moving items.

There’s a whole lot more we can do for you—let’s chat about your business needs together.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.