Running a business is all about strategy. And for retailers, your stock control strategy is one of the most important ones to have. The approach you choose isn’t just about keeping shelves stocked, it’s also about keeping operations efficient and profits steady. Every choice you make here shapes your bottom line.

One example? Choosing between push and pull inventory.

Push and pull inventory systems aren’t one-size-fits-all. Each one has unique benefits, and the right fit depends on how your business operates and what it needs. Knowing how they work can help you fine-tune your stock levels, cut down on waste and keep inventory aligned with demand.

- What is a push inventory management system?

- What is a pull inventory management system?

- Push vs. pull inventory management systems: a comparative analysis

- What is a push-pull inventory management system?

- Using a push and pull inventory management system: best practices

- How to choose the right inventory management system?

How to Manage Inventory Across Multiple Stores: A Complete Guide

Dive into the essential stock management best practices every multi-outlet retailer should know in this free guide.

What is a push inventory management system?

A push inventory management system is built around forecasting. Businessespredict demand using historical sales data, market trends and seasonal patterns, then plan their inventory levels accordingly. The idea is simple: produce or order stock ahead of time so it’s ready when customers need it—no waiting, no interruptions.

This model works best for businesses with steady demand or those that can take advantage of bulk purchasing. Think of retailers with predictable sales cycles or manufacturers producing at scale. The inventory moves through the supply chain—manufacturing, storage and finally to store shelves—before customers even place an order.

Benefits

- Control over production: A push system gives businesses more control over their supply chains. Manufacturing or purchasing schedules can be planned in advance, reducing downtime and ensuring smooth operations.

- Potential for bulk purchasing discounts: Buying in large quantities often leads to lower per-unit costs, which boosts profit margins. Bulk orders also cut down on shipping expenses.

Drawbacks

- Risk of overstocking: Forecasting isn’t always accurate. When demand is lower than expected,excess inventory can pile up, tying up cash and increasing storage costs. For perishable goods, this can lead to significant losses.

- Inflexibility to sudden changes in demand: Push systems don’t adjust well to unexpected shifts. A trend could change or customer preferences might shift, leaving businesses with unsold or outdated stock.

Push inventory systems offer predictability but aren’t without challenges. They rely heavily on accurate planning, which means the stakes are high—especially for businesses dealing with fluctuating demand.

What is a pull inventory management system?

A pull inventory management system is built around actual customer demand. Instead of predicting what might sell, stock is replenished only when orders come in. The flow of inventory is driven by what customers need—nothing more, nothing less. This approach keeps upfront investment low and avoids sitting on unsold stock.

Pull systems work well for businesses with unpredictable demand or those offering customized products. Production or procurement starts only when there’s a confirmed order. This reduces the risk of overstocking but requires a supply chain that can keep up with demand without delays.

Benefits

- Reduces waste and overstocking: Pull systems ensure you only order or produce what’s needed. This means less money tied up in unsold inventory and lower storage costs. It’s especially helpful for products with short shelf lives or trends that change quickly.

- Greater flexibility in responding to market changes: Because you’re not locked into pre-planned inventory, it’s easier to adjust to shifting customer preferences. Businesses can stay nimble while offering exactly what the market demands.

Drawbacks

- Potential for stockouts: Without extra inventory on hand, there’s always a risk of running out if demand suddenly spikes. This can lead to missed sales and frustrated customers if supply chains can’t respond fast enough.

- Requires efficient and responsive supply chains: Pull systems depend on tight coordination between suppliers and operations. Any hiccup—whether it’s a delayed shipment or a supplier shortage—can slow fulfillment and hurt customer satisfaction.

Pull systems are efficient and reduce waste, but they’re not without challenges. For businesses handling fluctuating demand or offering custom options, this strategy can be highly effective—but only if the supply chain is up to the task.

Push vs. pull inventory: a comparative analysis

Push and pull inventory systems take very different approaches to managing stock. Push systems rely on forecasts to predict demand and set inventory levels in advance. Pull systems, on the other hand, respond to real-time customer orders to determine how much stock is needed. Both have their place in retail, but their success depends on your business model, market trends and how you operate.

Key differences between push and pull systems

- Demand basis: Push systems use sales data and trends to estimate future demand. Pull systems wait for actual customer orders, making inventory more precise and tailored to current needs.

- Inventory levels: Push systems carry higher stock to avoid running out, while pull systems keep inventory lean to cut storage costs and minimize waste.

- Flexibility: Push systems lock you into pre-planned inventory—great for stable markets but risky if demand shifts unexpectedly. Pull systems are built for flexibility, adapting quickly to changes in customer preferences or trends.

Situations where each system excels

Push systems are ideal for businesses with steady, predictable demand. High-volume products, long production lead times or opportunities for bulk discounts make this approach cost-effective. Grocery stores stocking staples or manufacturers producing in large batches are good examples of where push systems shine.

Pull systems work better when demand is less predictable or when customization is key. Businesses tailoring products to individual customers or operating in fast-changing markets benefit from the responsiveness of pull systems. Think of boutique retailers, seasonal businesses or those with limited storage space—they’re perfect fits.

The right approach depends on what your business needs. Push systems offer stability for predictable operations, while pull systems are better for businesses that need flexibility. Some businesses even combine both—for example, using push for core inventory and pull for custom or fast-moving items.

| Feature | Push Inventory System | Pull Inventory System |

| Demand Basis | Uses forecasts and historical data to predict future demand. | Driven by actual customer orders and real-time demand. |

| Inventory Levels | Higher stock levels to prevent shortages. | Lower stock levels to reduce storage costs and waste. |

| Flexibility | Less flexible; locked into pre-planned inventory levels. | Highly flexible; adjusts quickly to market changes. |

| Ideal For | Businesses with steady, predictable demand (e.g., grocery stores, large-scale manufacturers). | Businesses with unpredictable demand or customized products (e.g., boutique retailers, seasonal businesses). |

| Benefits | More control over production, potential for bulk purchasing discounts. | Reduces waste and overstocking, adapts easily to market shifts. |

| Drawbacks | Risk of overstocking, inflexible to sudden demand changes. | Risk of stockouts, requires an efficient and responsive supply chain. |

What is a push-pull inventory management system?

A push-pull inventory management system blends the forecasting strengths of push strategies with the adaptability of pull strategies. It relies on demand forecasts to move inventory into the supply chain—think warehouses or distribution centers—but leaves the final steps, like restocking or production, to be driven by real-time customer demand. The goal is simple: combine stability with flexibility.

Here’s how it works. Inventory is pre-positioned based on predictions, ensuring products are ready where and when they’re likely to be needed. From there, the pull system takes over, using actual sales or order data to trigger what gets sent to store shelves or produced next. This setup helps businesses avoid overcommitting to inaccurate forecasts, reduce stockouts and keep lead times short.

Industries with complex product mixes or unpredictable demand are a natural fit for push-pull systems.Fashion retailers, for instance, often push staple items in bulk while pulling trend-focused pieces based on immediate demand.

Electronics companies do the same—pushing standard models to stores while pulling custom configurations or fast-moving accessories. By combining the best of both systems, businesses can balance cost control with the ability to meet customer needs in real time.

Using a push and pull inventory management system: best practices

Getting a push-pull inventory system right means knowing what your business needs, how it operates and what your market demands. It’s about balancing forecasting with real-time demand to keep stock levels optimized and costs under control. Here’s how to make it work.

Evaluate your product types

Look at your inventory and break it down by demand patterns and shelf life. Predictable, high-volume items—like staples or core products—fit well into the push side of the strategy. On the other hand, seasonal, customizable or trend-driven products are better suited for a pull approach. This kind of segmentation keeps your inventory flow efficient and tailored to your business.

Factor in market volatility

The more unpredictable your market, the more you’ll want to lean into pull strategies. Volatile markets or industries with shifting trends benefit from a pull approach—it keeps you from overstocking on items that might not sell. On the flip side, stable markets favor a push-heavy strategy, where bulk purchases lock in cost savings and ensure steady availability.

Build a responsive supply chain

Your supply chain needs to support both parts of the system. Suppliers must be able to fulfill quick reorders for the pull side, while your warehouse should handle bulk stock from the push side without delays. Strong communication with suppliers and demand planning tools can help prevent disruptions and keep everything running smoothly.

Use technology to stay ahead

Inventory management software is essential for tracking your stock and spotting trends across both systems. Real-time data lets you adjust quickly—whether it’s setting reorder points or refining forecasts. With the right tools, you can keep costs low, avoid stockouts and respond to customer demand without missing a beat.

A push-pull strategy works when it’s carefully planned and constantly refined. It’s not just about balancing two systems—it’s about making them work together for your business.

How to choose the right inventory management system

Choosing the right inventory management system starts with understanding what your business needs. It’s about aligning your inventory strategy with customer demand, supply chain capabilities and financial priorities. Here’s what to keep in mind as you narrow down your options.

Understand your demand

The type of demand your business faces is key. Are your products steady sellers all year, or do sales spike and dip with the seasons? For products with consistent demand, a push system can help you stay stocked and prepared. If demand is unpredictable or tied to trends, a pull system may be the better choice. Look at your historical sales data and trends—this will help you decide which approach fits your operations best.

Consider lead time and supply chain efficiency

Lead time—the time it takes for goods to move through your supply chain—matters more than you think. Longer lead times or complex supply chains can make a push system ideal by ensuring you always have stock ready to go. But if your suppliers are quick and reliable, a pull system can help you avoid overstocking and keep inventory lean. Take a hard look at how dependable your supply chain is and how quickly it can respond to changes.

Evaluate cost implications

Every system has its costs, and it’s important to weigh them carefully. Push systems often mean higher upfront expenses for bulk orders and storage, which can tie up cash flow. Pull systems, on the other hand, reduce storage costs but may lead to higher per-unit prices. Don’t stop there—factor in shipping and potential waste, too. The right choice balances your operational needs without straining your budget.

Assess flexibility and responsiveness

How adaptable is your business? If you need to adjust to fast-changing trends, a pull system offers that flexibility. It’s designed to respond to real-time demand, making it ideal for businesses that prioritize agility. On the flip side, if your focus is on consistent availability or you manage multiple locations, a push system offers the stability you need. Think about how quickly your business can pivot and whether your inventory strategy supports that.

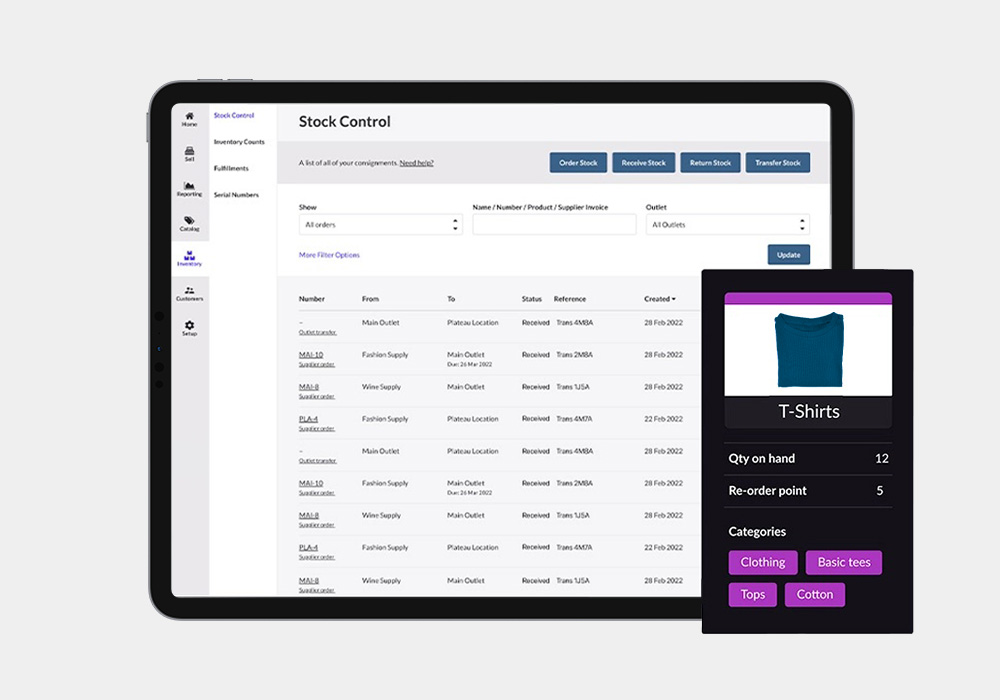

How Lightspeed helps you implement a winning inventory strategy

Whether you use push, pull, or a hybrid inventory strategy, Lightspeed Retail helps keep you in control. Automate stock tracking across locations, set reorder points to prevent stockouts, and speed up purchasing with built-in supplier catalogs.

Need flexibility? Manage inventory in real time across online and in-store channels. Plus, with powerful analytics, you’ll make data-driven decisions to optimize stock levels and maximize sales.

Bottom line

The right inventory management strategy keeps your shelves stocked and enables you to run your business efficiently. Push systems focus on planning ahead and saving with bulk orders, while pull systems keep stock lean and waste low. Hybrid strategies combine the best of both, balancing stability for everyday items with flexibility for changing demand.

Finding the right fit means looking at what your business needs most. Understand your demand patterns, assess your supply chain and use tools that help you forecast accurately and reorder efficiently. The right approach doesn’t just organize your inventory—it keeps your business competitive and ready to grow.

Talk to an expert to see how smarter inventory management solutions like Lightspeed can support your success.

FAQs

How can a business transition from a push to a pull inventory system?

Shifting from push to pull inventory doesn’t happen overnight—it’s a gradual process. Start by using real-time sales data to make inventory decisions based on actual demand instead of forecasts. Then, scale back bulk orders and work with suppliers to create a more flexible supply chain that can handle smaller, frequent restocks.

What are common challenges in implementing a hybrid push-pull inventory system?

Hybrid systems can be tricky because they require balancing two approaches. The push side needs accurate forecasts, while the pull side relies on a supply chain that can respond quickly to demand. Without proper tools to track inventory or clear communication with suppliers, it’s easy to run into delays, inefficiencies or even stockouts.

Is it possible to switch between inventory management systems based on seasonality or demand fluctuations?

Switching systems based on demand is doable—and often smart. A pull system works well during slower periods to avoid overstock, while a push system is better for handling bulk inventory during peak seasons. The key is having strong inventory tracking and reliable supplier coordination to make the transitions seamless.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.