Inventory visibility is at the heart of running a smooth retail operation. It shows you exactly where your stock is, how much you have and what’s available to sell—across all your locations and channels.

With that clarity, you can make confident decisions that protect your bottom line.

On the flip side—when visibility is off, the risks pile up fast. Overstocking eats into cash flow, stockouts frustrate customers and missed sales hurt growth. Businesses that can’t keep up with their inventory lose valuable ground to those that can.

Staying competitive means being aware of all things inventory in your business. Let’s break down what inventory visibility is, why it matters and how you can improve it.

- What is inventory visibility?

- Why is inventory visibility important?

- Challenges with poor inventory visibility

- Proven tips to boost inventory visibility

Grow your retail business.

Streamline inventory, suppliers, teams and stores with Lightspeed's all-in-one platform. From intuitive POS and stock management features to powerful reporting, Lightspeed gives you the tools you need to grow.

What is inventory visibility?

Inventory visibility is knowing exactly where your stock is, how much you have and what’s available to sell—at any moment. It means having real-time access to information about inventory levels, locations and availability across your business.

In supply chain and operations management, visibility ties everything together. It connects what’s in your warehouse, what’s in transit and what’s sitting on store shelves. This transparency helps businessesplan inventory, forecast demand and fulfill orders without missing a beat.

Not all visibility is the same, though. There are different ways to track inventory:

- Warehouse inventory visibility: Tracks stock stored at specific warehouses or distribution centers.

- In-transit inventory visibility: Monitors shipments between locations to keep delivery timelines accurate.

- Omnichannel inventory visibility: Combines inventory data across physical stores, ecommerce sites and third-party marketplaces.

Having real-time data for every unit of stock makes all the difference. It’s how businesses keep operations running smoothly and give customers exactly what they want, when they want it.

Why is inventory visibility important?

Optimized operations

Real-time inventory data makes it easier to allocate resources, avoid bottlenecks and keep shelves stocked across every channel. It cuts out the guesswork, so your team can focus on meeting demand without hesitation.

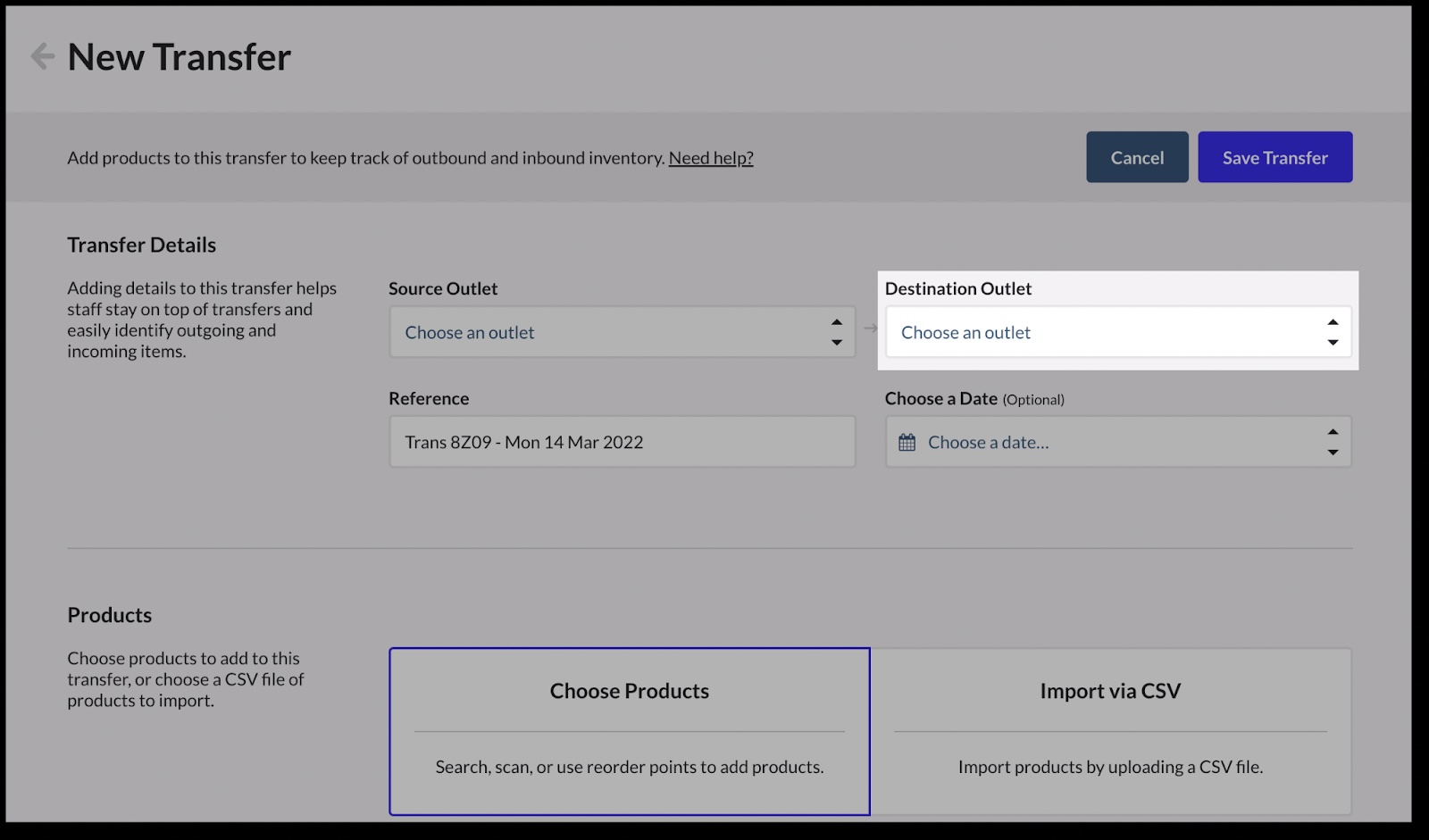

Lightspeed, for example, not only gives you realtime inventory visibility, it also lets you transfer stock from one location to another. That way, you can seamlessly move inventory between stores, ensuring customers always find what they need—without delays or missed sales.

Opulence of Southern Pines, a retailer that sells luxury bed and bath merchandise, streamlined multi-location inventory tracking with Lightspeed. By enabling real-time stock transfers and reducing manual errors, they eliminated inefficiencies and saved valuable time, so their team can focus on delivering exceptional customer service.

“My favorite feature is the inventory control…if my team needs something from another store, they’ll do a stock transfer, the other store gets it, they pull the merchandise, and it arrives within a week. It runs very smoothly,” says Tanda Jarest, Owner at Opulence of Southern Pines.

Cost efficiency

Inventory missteps are expensive. Overstocking ties up cash and drives up storage costs, while understocking leads to missed sales and unhappy customers. Strong visibility helps you strike the right balance—lowering carrying costs and protecting your bottom line.

Improved customer satisfaction

When inventory is accurate, customers notice. Visibility preventsstockouts and delays, so orders are fulfilled quickly and reliably. Delivering on expectations builds trust and loyalty, keeping your business top of mind for repeat purchases.

Data-driven decision making

Clear inventory visibility means smarter planning. With access to real-time data, you can forecast demand, spot trends and adjust buying strategies to stay ahead of shifts in the market. This insight helps you avoid over-ordering or running out of key products, supporting long-term growth.

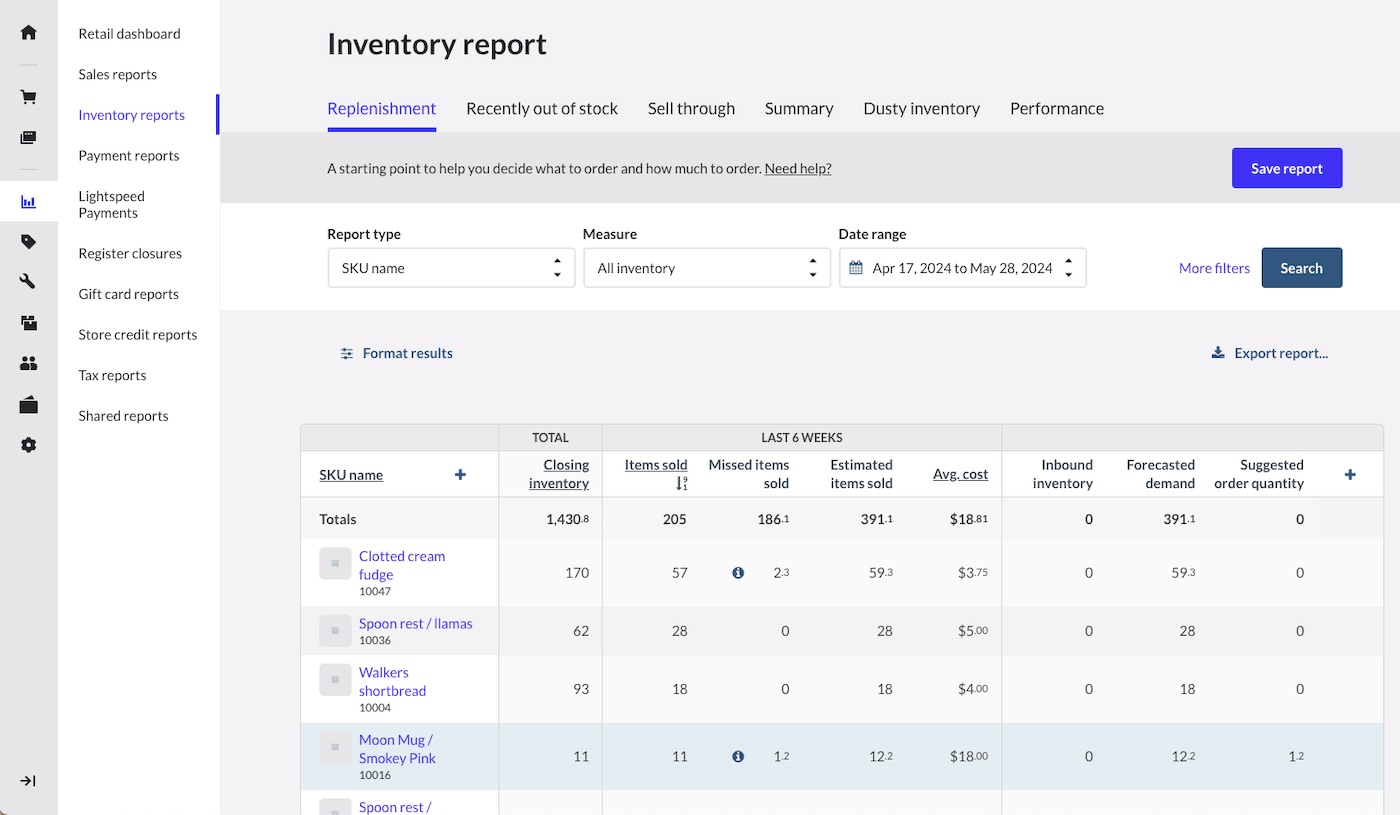

Speaking of demand forecasting, Lightspeed Insights makes this easy by providing you with actionable inventory data and recommendations. Aside from showing you how products are performing, Lightspeed surfaces re-order quantity recommendations based on your data.

No more second-guessing; with Lightspeed, you get data-backed reordering recommendations that help you maintain optimal stock levels.

If you’re using Lightspeed and on the Plus plan or have Advanced Reporting and Insights add-on, you can access this feature by navigating to Reporting > Inventory reports and clicking on the Replenishment tab.

Supply chain agility

Visibility gives you the flexibility to adapt when things change. Whether it’s a supply chain disruption or a sudden spike in demand, businesses with clear inventory data can pivot faster. That flexibility keeps service levels high and operations steady, even under pressure.

Challenges with poor inventory visibility

Poor inventory visibility doesn’t just create small hiccups—it sets off a chain reaction of inefficiencies and financial stress. Without real-time data, overstocking becomes routine.Excess inventory ties up cash flow, inflates storage costs and leaves products sitting unsold. The flip side? Understocking. Stockouts lead to missed sales and unhappy customers, many of whom won’t come back.

It’s not just about inventory levels—it’s also about how resources are used. Staff ends up wasting hours tracking down stock, fixing errors or handling frustrated shoppers when items aren’t available. That’s time better spent on tasks that actually drive revenue.

Take the example of a retailer using outdated tracking systems. They may assume they have enough of a top-selling item, only to realize during peak demand that shelves are empty. This disrupts sales, damages customer trust and makes forecasting nearly impossible. Overordering or underordering becomes the norm, shrinking margins and cutting into profits.

The longer these visibility gaps go unaddressed, the harder it gets to grow. Operational slowdowns, rising costs and lost sales build up—leaving businesses struggling to keep up with better-prepared competitors.

Proven tips to boost inventory visibility

Implement an inventory management system

Aninventory management system is the backbone of real-time tracking. It pulls all your stock data into one place, giving you instant visibility into inventory levels, movement and availability. Automated updates mean there’s no room for manual errors—just accurate, up-to-date information you can trust.

We’ve alluded to this earlier, but Lightspeed Retail offes leading inventory management software that gives you more visibility and control over your stock.

From tracking inventory across multiple locations to surfacing insights you can act on ASAP, Lightspeed helps you optimize operations, prevent stockouts, and streamline purchasing—all from one powerful system.

“[With Lightspeed,] we’ve grown the business 50% just [by] being able to track our inventory,” says Becky Boileau from The Plus Factor.

“We hired someone to plan our inventory and with Lightspeed, she can pull all the necessary reports, letting us know which categories are overstocked or understocked and what individual items we need to sell through,” she adds.

Integrate technology

Tools like RFID tags, IoT sensors and barcode scanners aren’t just nice to have—they’re game-changers for accuracy and efficiency. RFID and IoT provide real-time tracking for every item, while barcode scanning keeps processes like receiving and cycle counts quick and straightforward. Together, they reduce the time spent searching for stock and help eliminate avoidable errors.

Cloud-based solutions

Cloud platforms make inventory data accessible anywhere. They sync updates in real time across all locations, so you’re never second-guessing stock levels. Whether you’re in the store, at home or on the go, you’ll always have a clear picture of your inventory—ready to respond to demand shifts or supply chain hiccups.

Cross-department collaboration

Inventory visibility isn’t just about the tools—it’s also about teamwork. When sales, logistics and warehouse teams share the same data, everyone is aligned and better equipped to make decisions. Clear communication and shared visibility prevent stockouts, overstocking and last-minute surprises.

Accurate data entry and regular audits

Every well-oiled system starts with clean, accurate data. Train your team to follow strict entry protocols and double-check records to keep discrepancies at bay. Regular audits andcycle counts act as a safety net, catching mistakes early and ensuring your inventory data stays reliable. It’s a small effort that pays off with smoother operations and sharper visibility.

Bottom line

Inventory visibility isn’t just a nice-to-have—it’s what keeps your business running smoothly and profitably. Real-time tracking shows you exactly what’s in stock, what’s selling and what needs attention. It helps you avoid overstocking or running out of popular items, giving you the control to meet customer demand without hesitation.

When inventory is clear, businesses operate with confidence. Supply chains move faster, costs stay under control and sales aren’t lost to errors or delays. Even better, customers notice the difference. Reliable stock and faster fulfillment create experiences that build trust—turning first-time buyers into loyal, repeat customers.

The best way to improve visibility is starting with tools that centralize your data and remove manual guesswork. Look for systems that update in real time and connect seamlessly across all your sales channels.Watch a demo to see how better visibility can elevate your business today.

FAQs

How can businesses improve inventory visibility?

Improving inventory visibility starts with the right tools. Inventory management systems with real-time updates are essential—they keep stock data accurate and accessible across all channels. Adding tools like barcode scanners, RFID tags or IoT sensors makes tracking faster and more precise. Regular cycle counts and audits also play a big role by catching errors early and keeping your data dependable.

What is global inventory visibility?

Global inventory visibility is the ability to see your stock—everywhere, all at once. It covers inventory across warehouses, stores and ecommerce platforms in real time, giving businesses a single, centralized view. With this level of insight, you can allocate stock more efficiently, avoid overstocking and stay flexible when demand shifts—no matter where your inventory is stored.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.