Inventory shrinkage is the bane of retailers everywhere. Even a moderate amount of shrinkage can have a big impact on your business, which is why it’s important to get your shrinkage rates as low as possible.

Don’t worry, though—we’re here to help you out. In this post, we’ll go over:

- What is inventory shrinkage?

- What causes inventory shrinkage?

- How to calculate inventory shrinkage

- How to control inventory shrinkage

Profit and Loss Template

Examine the financial health of your business by highlighting exactly how much revenue is being generated versus what’s being spent.

What is inventory shrinkage?

Inventory shrinkage is when you lose inventory due to factors other than sales. It can generally be defined by the difference between your inventory levels on paper and your actual inventory levels. Every retailer across every industry is impacted by shrink, with organized retail crime being one of the industry’s prime concerns (but not, notably, the only cause of shrink).

What does shrinkage mean for retailers?

If your inventory management system says you have 10 pairs of shoes in stock, but you actually have 9 on hand, and you can’t account for that lost pair through sales, your inventory has experienced shrinkage.

Shrinkage hurts retailers in two key ways:

- Lost cost: when your inventory is lost to shrinkage, you’ve thrown the expenses involved in acquiring that stock out the window.

- Lost profits: inventory represents more than just its cost to acquire. All of the stock on your shelves is potential cash flow waiting to be freed up by a sale. If your inventory shrinks, you have less assets available to acquire new inventory, pay sales staff and grow your business.

Types of retail shrinkage

Inventory shrinkage can be broadly classified into three categories: loss, damage and operational mistakes.

Here’s a quick description of each of these types of shrinkage:

- Loss. If your inventory has shrunk due to loss, the items in question are no longer in your possession. Typically, this is because of internal and external theft. You paid for these items, and can no longer sell them.

- Damage. If damage has occurred, your sellable inventory has shrunk, but the item itself may still be in your possession (depending on the extent of the damage). Damage often requires disposing of an item. It’s sometimes possible to repair damaged merchandise or sell it as-is, but you’ll lose out on revenue due to either repair costs or discounted prices.

- Operational mistakes. Merchandise may have been miscounted or shipments may have been entered incorrectly. With operational mistakes, shrink is more theoretical—you never had that inventory in the first place, but your teams were operating under the assumption that you did.

What factors contribute to or cause inventory shrinkage?

Inventory shrinkage doesn’t have one singular cause. The best way to combat shrinkage is to know where yours is coming from.

Here are some common causes of shrinkage.

Shoplifting

When most retailers think of shrink, they think of theft, or shoplifting.

But shoplifting is more than just straightforward theft. Price tag swapping also falls into this category, where a shoplifter pays less than what an item is worth because a different item’s SKU is recorded in the sale.

Organized retail crime, where two or more people conspired to steal merchandise to resell, also falls under the shoplifting label.

According to the National Retail Federation’s 2022 Retail Security Survey, shoplifting (of all kinds) is the biggest source of shrink.

Employee theft

Employee theft, also known as internal theft, is a significant contributor to shrinkage. The NRF’s survey found it was the source of 28.5% of inventory shrinkage, second only to shoplifting (external theft).

Theft, fraudulent returns and neglecting to scan items for friends and family lead to mismatches in your inventory levels and can add up to big losses for your business.

Human entry error

Poor inventory management isn’t just frustrating. It can lead to shrinkage as well. Whether it’s misclassifying a product, a typo in a name, scanning a shipment twice or incorrectly entering numbers after a cycle count, if your records are off, your reorder and revenue calculations are off. When you correct those records, you might end up with shrinkage.

On its own, shrinkage due to administrative errors doesn’t necessarily mean lost cost—but it does mean lost profit, as you were likely forecasting more revenue than your actual inventory numbers can bring in.

Vendor error and theft

Vendors can be subject to the same administrative errors as retailers, which can contribute to shrinkage. Both you and your vendors can the risk of human entry error by using online B2B platforms like NuORDER.

Some dishonest vendors can steal from you by not delivering a full order, though this is, by far, not the way the majority act. Vendor theft is not a very large contributor to shrinkage, and many retailers will not fall prey to it.

Damage

Accidents happen! Sometimes goods are broken without any theft or administrative error being at fault.

How to calculate inventory shrinkage

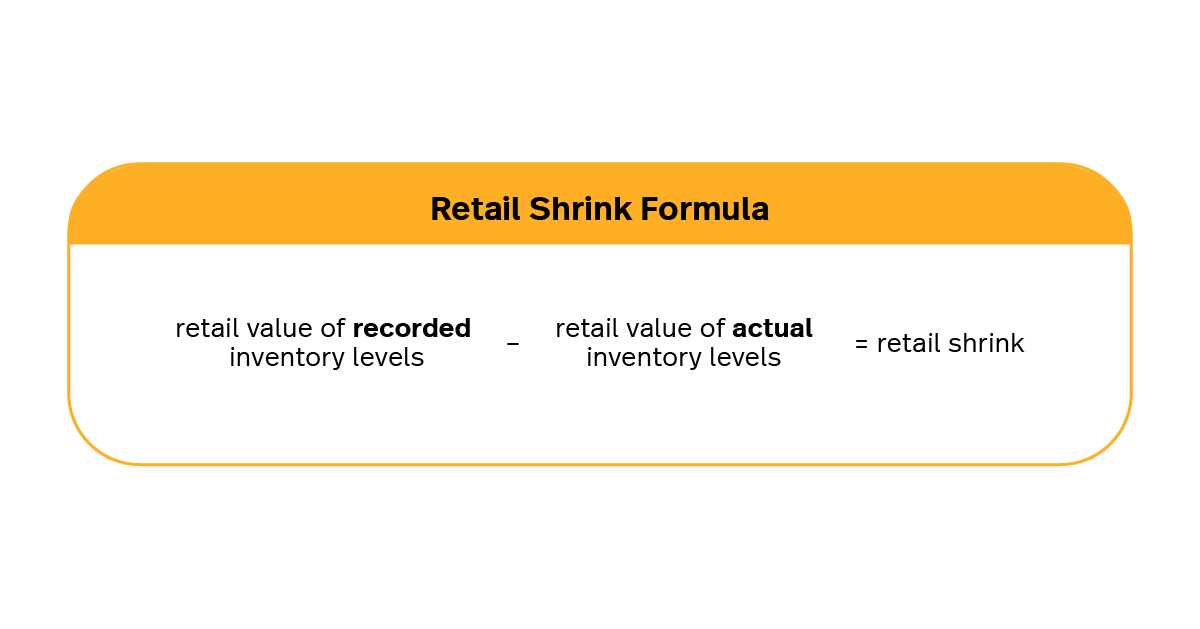

Every time you sell an item, the value of your inventory on hand is reduced by the price of that item. Conversely, whenever you place a new order of stock, the value of your inventory increases by the amount you ordered. Your shrinkage is whatever discrepancies arise between the sales and orders you have recorded and the actual value of the inventory you have on hand.

Let’s say you have $200,000 worth of inventory according to your records. You do an inventory count and find you actually have $197,000 on hand. Your inventory has shrunk by $3,000.

So to calculate retail shrinkage, we follow this formula:

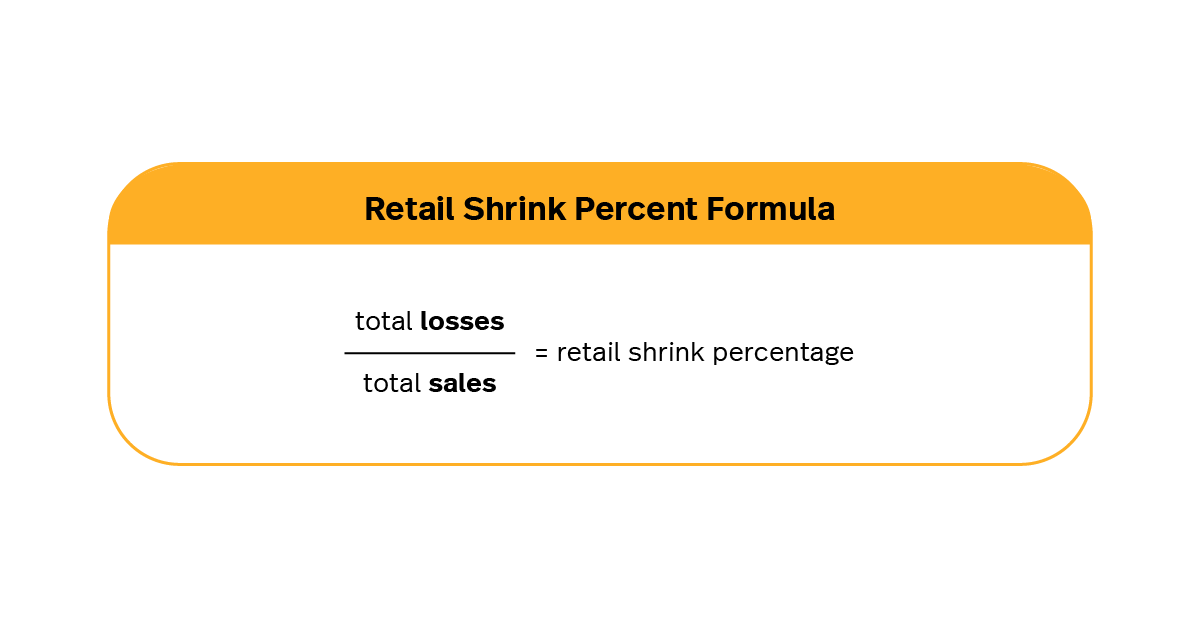

To better understand the impact of shrinkage, we can calculate it as a percentage in relation to your total sales. If we want to express retail shrinkage as a percentage, we follow this formula:

What is an acceptable inventory shrinkage rate?

In 2020, the retail industry’s average shrink rate rose to all-time high recently, after years of holding steady.

That all time high?

1.62%.

It doesn’t take much shrinkage to make a noticeable impact on your business. Even with shrinkage lowering to 1.44% in recent years, that number translates to over $94 billion lost.

As such, an acceptable inventory shrinkage rate is as small as possible.

Inventory shrinkage management: how to control inventory shrinkage

Unless you find a way to completely eliminate accidental damage, you’ll always have some inventory shrinkage over the course of your business’s lifetime.

However, there are things you can do to get your shrinkage rate as low as possible.

Employ frequent cycle counting

If you’re not keeping an eye on your inventory levels, you’re vulnerable to being blindsided by shrinkage rates that you never even knew were a problem. However, full physical inventory counts are prohibitively time consuming—there’s a reason most retailers only count their entire stock once or twice a year.

Good stock management practices will help you keep on top of inventory shrinkage, though, so implement frequent cycle counting practices instead.

Cycle counting refers to the practice of counting a small amount of your inventory on an ongoing basis. You might do a weekly count of 10 different SKUs, for example, or you might pick 20 particular SKUs to count weekly for a month to monitor stock level changes for those products.

Either way, here’s how the process works:

- Pick a section of your store to focus on.

- Count the SKUs in that section of the store. You can make this part faster and more accurate by using a counting app like Lightspeed Scanner, which connects an iOS device to your POS for instantaneous stock level updates.

- Compare the count to the stock levels in your inventory management software.

The goal is to always be on top of your inventory reconciliation to catch shrinkage as it happens. If you have inventory that’s at particular risk for theft, such as batteries or low-cost accessories, consider focusing multiple cycle counts in a row on those SKUs.

Cycle counting is more of a warning system than an inventory shrinkage deterrent in and of itself, however. It helps you pinpoint where shrinkage may be happening and if you need to invest more in your loss prevention strategies.

Implement anti-shoplifting measures

Shoplifting is a serious contributor to shrinkage, so it’s worth it to take the time to invest in anti-shoplifting measures.

Your sales staff can be an important shoplifting deterrent. They should never put themselves in harm’s way, but greeting every customer and making it clear employees are alert can discourage potential shoplifters.

In addition to training your staff, loss prevention tools include:

- Electronic security tags: these are those plastic tags that can only be safely removed by staff at the front counter. They can either sound an alarm when the tagged merchandise is carried out of the store or ruin the product in some way, such as with ink, when tampered with.

- Security cameras: security cameras installed throughout your store are a powerful anti-shoplifting deterrent. To avoid alerting potential shoplifters of blindspots in your store’s security system, consider hidden cameras with signage indicating shoppers are being recorded. If any shoplifting does happen, you can consult your camera footage for visual evidence. Security cameras are also effective in lowering employee theft.

Mitigate employee theft risk factors

Unhappy and under-trained employees are risk factors for theft.

Because sales staff who steal may do so because of external life stress or internal strife, one of the easiest ways you can cut down on theft is by having an open line of dialogue with your employees.

Trust and high morale can go a long way. If employees know they can come to you about working conditions, they’re more likely to speak up about what they need instead of taking it from you.

In addition, you could consider:

- A buddy system: there should always be at least two employees working at all times. Ensure voided sales and refunds require another employee, preferably a manager, to be present.

- An anonymous tip line: whether you do this by email, phone or online form (such as a Google form), make sure employees have a way to remain anonymous. Employees who witness theft may be more willing to report it if they won’t be found out by their co-workers.

Use an all-in-one system for less admin errors

One of the best ways to cut down on human entry error is to remove the human entry part. With a fully connected inventory management and point of sale system, you can worry less about mismatched numbers.

An integrated system makes decisions about what to do about shrinkage easier, too, because you have a lot of the information you need on hand for easy reference.

If you’re using a POS system like Lightspeed, you can check your inventory levels and past cycle counts at a glance, making it simpler to monitor potential shrinkage rates. Cycle counts also take less time, because you can scan inventory levels directly into the system—which cuts down on potential administrative errors entering the counts.

Invest in item tracking or theft deterrent

The fashion industry is a master at this—just think about those ink-blot tags many stores use, making it difficult to make use of stolen goods without ruining them. For bigger ticket items, you could attach item tracking tags that are deactivated by staff when customers check out.

Alternatively, or in addition to the tags, you could lock particularly valuable inventory behind glass cases. This ensures employees need to speak to customers before they can touch these items, which both deters theft and gives employees a chance to upsell to customers.

Create an inventory shrinkage action plan

Time to tackle your inventory shrinkage!

- If you’re not already using one, switch to a fully connected inventory management and point of sale system.

- Evaluate your current loss prevention measures. Consider implementing electronic tags and security cameras if you haven’t already.

- Examine your employees’ shifts and ensure at least two employees are working at all times.

- Establish an anonymous employee theft tip line and inform employees. Emphasize that all reports are truly anonymous.

- Find ways to increase employee morale so they’re less likely to engage in theft.

- Set up your cycle counting schedule. Clearly define how you’ll pick SKUs to count each week and write out the steps for cycle counting employees.

If you’re interested in learning how Lightspeed Retail POS could help you cut down on administrative errors and speed up how you work, let’s talk.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.