Effective supply chain management can save businesses both time and money. Two of the most important components of supply chain management include efficient inventory management and accurate demand planning and forecasting. While deeply connected, each serves a different but equally important purpose.

Supply chain management encompasses all the processes involved in sourcing, procuring, producing and distributing goods. The supply chain starts with the flow of raw materials and ends with getting products in the hands of customers.

Ultimately, business owners around the world have been impacted by supply chain issues. From a reduced demand for goods, geopolitical unrest, rising inflation costs and severe weather events, there are plenty of obstacles that disrupt the flow of goods.

That’s why it’s important to tap into the factors you can control when it comes to supply chain management. Inventory planning and demand forecasting are two areas where you have the most control, and that can make an important difference in your bottom line.

In this article, we’ll discuss the differences between these two key areas. We’ll cover:

- What is inventory planning?

- What is demand forecasting?

- Key differences between inventory planning and demand forecasting

- How inventory planning and demand forecasting work together

A guide to multistore inventory management

Check out our guide to the stock management practices every multi-outlet retailer should know.

What is inventory planning?

Inventory planning is the process of determining the correct amounts and timing of inventory to accurately meet customer demand, while minimizing costs and growing profits. Inventory planning serves many purposes. Here are just a few:

Preventing stockouts

Timing is key: knowing your bestsellers and peak sales periods helps determine your inventory needs. Using this information, you can order with ultimate accuracy to prevent popular products from going out of stock. This way, you won’t lose out on potential sales and customers.

Reducing overstocks

The point of inventory planning is to maintain optimal stock levels to maximize sales. Consequently, overstocking is just as much of an issue as stockouts. When your capital is tied up in inventory that isn’t moving–for instance, if you ordered too much of one item that didn’t end up selling–you’re tying up cash flow that could be utilized much more effectively. In order to avoid this, proper inventory planning is crucial so that you’re ordering the right items, at the right time, to keep inventory moving.

Optimizing cash flow

Strong inventory planning means strong cash flow. When you maintain the perfect stock levels at any given time, you’re also optimizing your cash flow. Your capital isn’t tied up in inventory because it’s selling, which is the ideal situation. It goes all the way to manufacturing–if you order inaccurate quantities of an item but fail to meet actual customer demand, you’re jeopardizing your cash flow.

Lowering holding costs

With accurate inventory planning, you reduce expenses related to holding inventory because it’s moving consistently. That includes storage fees, insurance, and product handling costs.

What is demand forecasting?

Demand forecasting is the process of predicting future customer demand based on factors such as historical data, market trends, sales reports, consumer preferences and more. Demand forecasting plays an integral role in inventory management. Here’s how:

Improves inventory planning

Being able to predict future consumer demand makes inventory planning simpler. Demand forecasting helps determine optimal stock levels, ensuring you’re ordering based on customer needs assessed through real data.

Boost production planning

Demand forecasting simplifies production scheduling, ensuring alignment with future demand. This prevents manufacturers from either overproducing or underproducing stock, ultimately improving overall supply chain efficiency.

Efficiencies across the production process

Better informed decision making through accurate demand forecasting enables agility and coordination across your supply chain. Not only are you ensuring that raw materials are available when needed, your relationships with suppliers will improve because you’re able to plan ahead.

Improves customer satisfaction

It’s simple: the more accurate your forecasts, the more satisfied customers will be. By responding to the needs of your customers, you position your business as a consistent place to shop. Customer loyalty will increase, and they won’t be driven to your competitors.

Related: Read our guide on the retail inventory method.

Key differences between inventory planning and demand forecasting

Here’s handy table for you to reference before we get into the details.

| Aspect | Inventory planning | Demand forecasting |

| Primary focus | Managing inventory levels | Predicting future customer demand |

| Time frame | Immediate to short-term | Medium- to long-term |

| Data source | Real-time inventory levels and lead times | Historical sales data, market trends, analysis |

| Decision-making | Day-to-day adjustments for current stock needs | Strategic planning for long-term inventory needs |

| Goal | Ensure stock meets current demand | Align stock with anticipated future demand |

When it comes down to it, the simple difference between inventory planning and demand forecasting. respectively, is managing inventory levels compared to predicting future demand (forecasting). Timing and data are two key differentiators.

Timing

Inventory planning is typically based on immediate and near-term needs, while demand forecasting looks at the medium- to long-term.

With inventory planning, business owners must make day-to-day decisions, focusing on ensuring current stock levels meet demand. If that’s not the case or there are current supply and demand changes, adjustments have to be made.

Demand forecasting operates differently. Depending on your industry, market, and business size, demand forecasting covers a longer time frame–several months to even years. Demand forecasting tends to be more strategic, providing insights into long-term inventory needs and broader supply chain requirements.

Data

Inventory planning relies primarily on current inventory levels. Accurate, real-time data on stock levels is essential for making effective decisions. Knowledge of inventory lead times–the amount of time it takes for warehouses to receive shipments after purchase orders are made–is also critical. Understanding lead times allows businesses to order inventory at the right time, preventing both overstocking and stockouts.

On the other hand, demand forecasting relies on historical data. Past sales data and trends are used as a baseline, while adjustments are made based on seasonality, peak periods, promotions and other considerations. In addition, market analysis plays a significant role in demand forecasting. That includes economic indicators, competitor research and overall industry trends. Combined, all of these factors make for more accurate forecasting, ensuring you can predict consumer needs to align with sales goals.

Interdependencies

While these processes are different, they work together as a foundation for strong inventory management. That means you’ll need to rely on longer-term forecasts to inform your short-term planning decisions, if only to avoid making reactive decisions.

It goes the other way, too. Demand forecasts can be refined based on real-time inventory and sales reports. Because the market can fluctuate, it’s important not to have tunnel vision or exclude real-time data entirely from forecasts.

Managing stock levels vs. Predicting future demand

In the demand forecasting vs. inventory management debate, inventory management focuses on maintaining optimal stock levels for day-to-day operations. It relies on current data to prevent stockouts or overstocking. Meanwhile, demand forecasting looks ahead to predict future sales. While inventory management handles immediate needs, demand forecasting helps businesses plan strategically for the future.

Inventory tracking vs. Data-driven projections

The difference between inventory planning and demand forecasting lies in the type of data used. Inventory planning focuses on real-time stock levels to manage short-term replenishment, balancing supply and demand immediately. Demand forecasting, however, uses historical data, trends and market insights to project future demand, allowing businesses to plan ahead and optimize inventory.

Preventing stockouts vs. Aligning supply with demand

Preventing stockouts focuses on ensuring that products are always available when customers need them. It’s reactive—addressing supply gaps by closely monitoring inventory levels, and restocking when necessary. In contrast, aligning supply with demand is more proactive. To do this, retailers will forecast future demand, and ensure that their supply reflects it.

Common demand forecasting and inventory planning challenges

Data inaccuracies

One of the biggest challenges in demand forecasting accuracy is using the right data. Inaccurate or incomplete historical data can lead to poor forecasts, causing imbalances like stockouts or overstocking.

Retailers need to ensure their data is consistent, up-to-date and easily accessible to improve forecasting accuracy and make better inventory decisions. Then, retailers must take action to ensure that they have adequate supply to meet this demand.

Seasonal demand fluctuations

Fluctuating seasonal demand can make forecasting and inventory planning tricky. While businesses often see sales spikes at certain times of the year, predicting exactly how much the demand will increase can be difficult. If businesses don’t plan for these changes properly, they may end up with too much stock or not enough to meet customer needs.

To handle these inventory planning challenges, retailers can leverage data from previous seasons to get a better sense of the seasonal demand they need to prepare for. Retailers can also use inventory management software to automatically adjust stock levels based on these past trends, making it easier when a new shopping season arises.

Supplier lead time variability

When lead times are inconsistent, it’s hard to plan effectively. Variations in lead times can cause delays or shortages, especially if inventory forecasts are based on inaccurate or outdated timelines.

To reduce this risk, retailers can work to maintain good relationships with suppliers, keeping in regular contact about potential delays. Retailers should also consider working with multiple suppliers to avoid relying on just one.

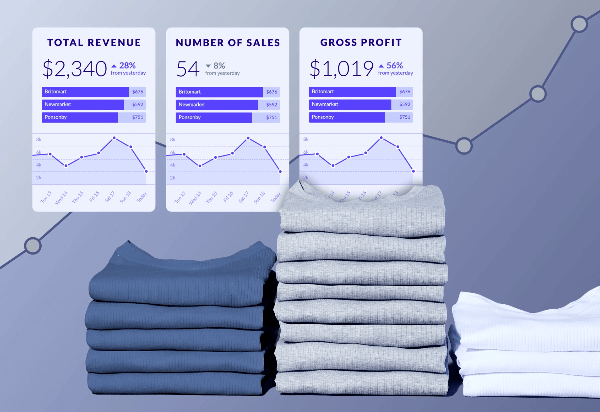

Did you know? Lightspeed Inventory Management and Lightspeed Insights work together to ensure smooth and successful inventory planning and accurate demand forecasting. You get a full view of your stock levels, sales and historical data. Both real-time and past data work together to create a seamless process for your business, so you can grow faster.

How inventory planning and demand forecasting work together

Accurate demand forecasting informs inventory planning decisions, and vice versa. Together, they help businesses align stock levels with demand, improve order timing, reduce waste and boost cash flow.

Both processes are streamlined with the use of integrated systems, ultimately improving supply chain efficiency. This can look like a POS platform with built-in inventory management software, for instance. Some benefits of using an integrated platform for demand forecasting and inventory planning:

- Real-time synchronization: When your sales and inventory are connected, you will get real-time updates on stock levels with each transaction. You can always rely on the fact that your inventory is up to date, saving a lot of time and ensuring greater response times.

- Faster ordering: With all the data you need at your fingertips, you can make faster purchasing decisions. Typically, recommendations will be automated as well–based on factors like stock levels, customer trends and lead times.

- Data to enhance decision-making: You’ll have clear visibility into your inventory needs at all times with actionable sales and stock data, empowering decisions that boost your business’s growth.

Potential challenges

When inventory planning and demand forecasting processes aren’t aligned, there are a few challenges that can come up.

- Lost sales: This is a big one. Your bottom line is impacted when misalignment occurs, leading to stockouts. Consequently, you’ll miss out on sales opportunities, face dissatisfied customers and potentially even lose customers.

- Increased costs: Poor planning and forecasting could lead to excessive inventory costs due to overstocking. Not to mention, resources may be misused, resulting in higher operational costs as well.

- Lack of visibility: It’s difficult to plan well when you lack visibility into your inventory needs. That’s why data is so important–optimal stock levels are achieved through both real-time reporting and historical information. This will save you a lot of time, money and guesswork.

All of these challenges can be mitigated by using an integrated solution. As your business grows, the solution you use should grow with it to meet your complex inventory needs. For instance, automated data reconciliation is one feature of an integrated solution that will help you identify discrepancies.

The bottom line

When it comes down to it, your business needs accurate inventory planning and demand forecasting to thrive. Both your short-term and long-term profits rely on it.

They provide a foundation for strong supply chain management, allowing you to meet customer demands at every turn and grow your sales.

Looking for a strong inventory and supply management system? Talk to a Lightspeed expert today.

FAQ

What tools are commonly used for inventory planning and demand forecasting?

Inventory planning and demand forecasting typically use tools like inventory management software, integrated POS systems and data software.

How do small businesses approach these processes compared to large enterprises?

Small businesses may use simpler tools such as spreadsheets or ultrabasic inventory software because of budget constraints. Large enterprises tend to use advanced, integrated systems that provide forward planning and better support their complex needs as they grow.

What are the risks of poor inventory planning or inaccurate demand forecasting?

Inadequate inventory planning and demand forecasting can lead to stockouts, overstocking, a lack of supply chain coordination and wasted resources.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.