Inventory management is crucial in business—but it can be easier said than done. Without full visibility into what you have and what people want, you can easily find yourself ordering too much stock—at the risk of never moving it—or ordering too little, leading to stockouts and frustrated customers who’ll start looking elsewhere.

The solution? Good inventory management techniques. Let’s dive into 16 key techniques that can help you optimize stock levels, reduce carrying costs, avoid dead stock and give customers what they want (when they want it).

Here’s what we’ll cover:

- Demand forecasting

- ABC analysis

- Safety stock

- Reorder points

- PAR levels

- Just-in-time (JIT) inventory

- Dropshipping

- Cross-docking

- Inventory management software

- FIFO and LIFO

- Consignment inventory

- Economic order quantity (EOQ)

- Perpetual inventory management

- Minimum order quantity (MOQ)

- Bulk shipping

- Batch tracking

16 essential inventory management techniques

1. Demand forecasting

Demand forecasting is the process of predicting future demand for your products based on historical data, trends and market analysis. It’s a critical part of running a business—without it, you’re basically running your business blindfolded.

With accurate demand forecasting, you can make sure you have the right amount of inventory to meet demand—reducing the risk of stockouts and frustrated customers—and avoid heaps of unwanted goods left to die in your storeroom or warehouse. Demand forecasting also facilitates better planning, from more accurate budgeting to better resource allocation and supply chain management.

2. ABC analysis

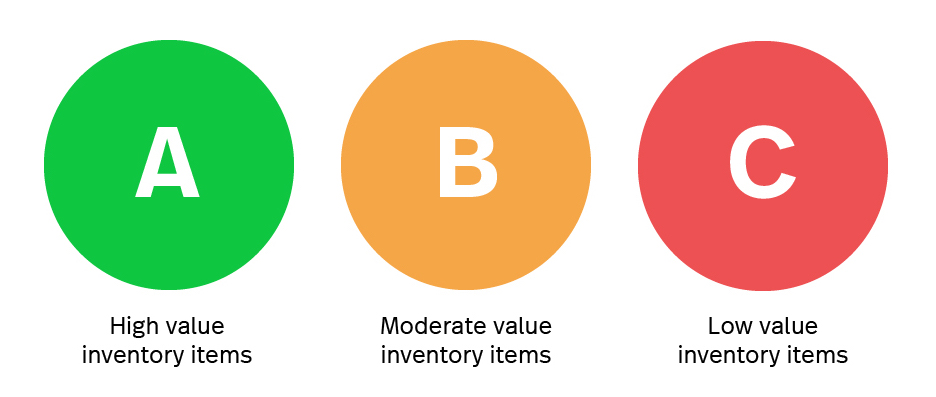

ABC analysis is an inventory management technique that classifies inventory into categories based on its value or importance to the business’s overall profit.

- Category A: most valuable items, usually based on sales volume, profit margin or cost to acquire. Category A items often make up a small percentage of total inventory but bring in the majority of revenue. These items need close monitoring and tight inventory control.

- Category B: important items, but less important than Category A items due to lower profitability or sales volume. These items require attention and monitoring, but not at Category A levels.

- Category C: items with the least impact on sales and lowest profit margins. These items often account for 50% or more of total inventory but contribute the least to revenue, thus requiring minimal oversight.

By prioritizing inventory that has the biggest impact on their bottom line, businesses can apply the appropriate controls and resources required to manage it.

3. Safety stock inventory

Safety stock is the extra stock you order beyond your forecasted demand. It’s effectively a buffer between you and stockouts, accounting for uncertainties like unexpectedly high demand, supplier delays or temporary outages.

So how much safety stock should you keep on hand? TL;DR, there are a number of formulas that retailers and inventory managers use to calculate safety stock levels, but here’s the basic formula:

| Safety stock = (maximum daily sales x maximum lead time) – (average daily sales x average lead time) |

To use this formula, first check your sales over a given period of time—say, a month. Then gather the following data for each SKU:

- average daily sales

- maximum daily sales

- average lead time

- maximum lead time

To keep it simple, let’s say your business only sells one SKU—a candle. On average, you sell 50 candles a day, but on one day of that month, you sold 100 candles. And you usually receive new shipments from your supplier within four days of submitting a purchase order. However, it’s taken as long as 12 days to get your order that month.

Here’s what that gives you:

average daily sales = 50

maximum daily sales = 100

average lead time = 4 days

maximum lead time = 12 days

Now you can plug in your numbers and start crunching:

| Safety stock = (100 x 12) – (50 x 4) Safety stock = 1,200 – 200 Safety stock = 1,000 |

Using this formula, you would keep 1,000 extra candles on hand at all times.

4. Reorder points

Reorder points are basically the lowest acceptable level of inventory before you need to reorder, taking into account an item’s sales volume and lead time. Any lower than that, and you’re in the danger zone for stockouts and unhappy customers.

So, how do you figure out reorder points for your inventory? Well, there are three key variables to consider for a basic reorder point calculation: average daily sales, lead time and safety stock. The formula is:

| Reorder point = (average daily sales x delivery lead time) + safety stock |

Luckily, we covered how to calculate safety stock in the section above. So using the same example as above, the reorder point calculation for your candle store—which inexplicably sells only one candle—would look like this:

Reorder point = (50 x 4) + 1,000

Reorder point = 200 + 1,000

Reorder point = 1,200

Learn more about calculating reorder points.

5. PAR levels

Periodic automatic replenishment (PAR) is an inventory management technique that involves setting a maximum and minimum quantity for each inventory item. These maximums and minimums are referred to as PAR levels.

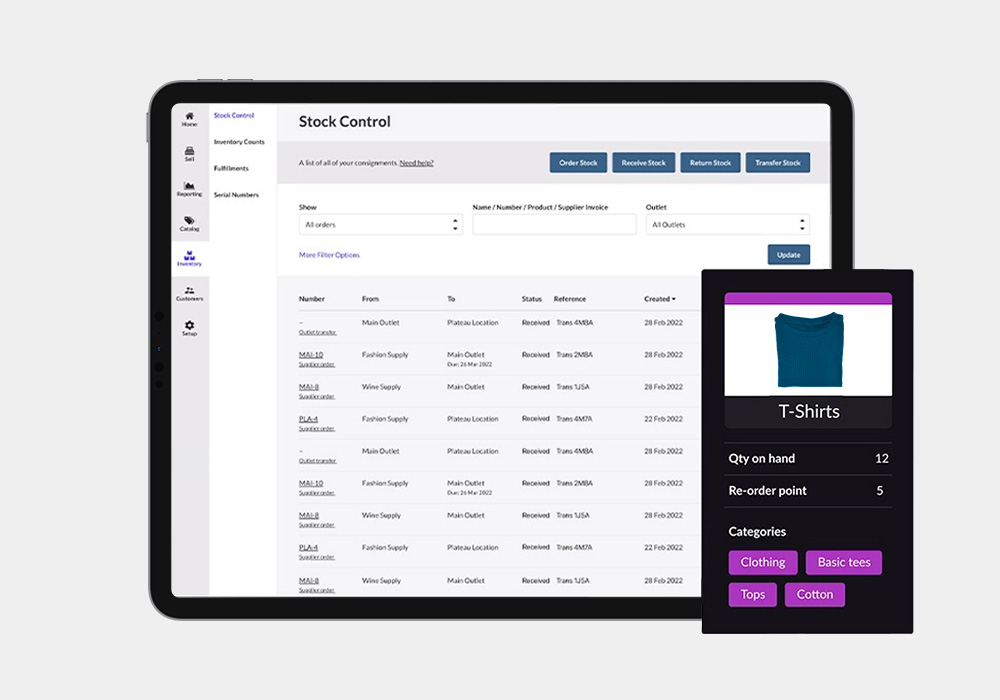

When inventory for a product approaches the minimum PAR level, the item should be reordered. Using inventory management software like Lightspeed, you can set reorder points that will automatically trigger a reorder to help bring your inventory back up to PAR.

Here’s how it works:

- From your product catalog, select the product you want to create a reorder point for.

- Select ‘Edit product’, then scroll down to the ‘Inventory’ section.

- Under ‘Inventory levels’, enter the item’s reorder point in the ‘Reorder point’ field (grab the reorder point formula in the section above).

- Set the default reorder quantity in the ‘Reorder quantity’ field.

This automatic process helps ensure that stock is replenished before it runs out, preventing stockouts and ensuring smooth operations.

6. Just-in-time (JIT) inventory

The just-in-time (JIT) inventory management method focuses on keeping as little inventory on hand as possible. So instead of ordering inventory or supplies in advance to be ready to meet forecasted demand, JIT involves ordering small shipments to replace inventory as you forecast and fulfill orders.

Sounds great, right? But there’s a catch—you need to have stable demand and very reliable suppliers. Even then, you may be at a higher risk of stockouts and missed sales due to supply chain disruptions.

7. Dropshipping

Inventory management doesn’t get easier than dropshipping, primarily because you don’t actually keep any inventory on hand. Dropshippers work with a third party supplier who ships the order directly to the customer when an order is placed. Here’s how it works:

- A customer places an order on your online store.

- You forward the order to your supplier and pay the wholesale price.

- The supplier prepares and ships the product directly to the customer.

- The customer receives the product, and you keep the profit from the sale.

Keep in mind that you—and not the supplier—are responsible for customer aftercare, including handling any complaints or customer refunds.

8. Cross-docking

Cross-docking is a technique for managing inventory that essentially skips the storage part of inventory. Instead of moving inventory into the warehouse to be shipped out later, product moves directly from the receiving dock to the shipping doc for immediate loading onto outbound trucks. Here’s how that works:

- Goods are received from inbound trucks.

- Goods are unloaded, sorted and reorganized.

- Goods move from the receiving dock to the shipping doc.

- Goods are immediately loaded onto outbound trucks for shipment.

Cross-docking can speed up delivery times, minimize the need for warehouse space and reduce inventory handling and holding costs. However, it requires precise coordination with suppliers and may not be appropriate for businesses with low product turnover.

9. Inventory management software

Inventory management software helps retailers track inventory, accurately forecast demand, streamline processes and ultimately reduce costs.

The best inventory management software for your retail business depends on your specific operations and needs. Here are some key features to look for when choosing inventory management software:

- Real-time updates: automatically updates inventory levels as products are sold or received, ensuring accurate stock counts, so you can prevent stockouts and overstocking with up-to-date insights into what you have on hand.

- Automated reordering: automatically adds products to your low stock report when they reach your pre-set “danger zone” and auto-populates a reorder for you, so you can make sure you’ve got enough of what you need, when you need it.

- Multi-location inventory management: connects all your locations and sales channels, whether they’re on site, online or in warehouses or distribution centers, allowing you to track and manage all your inventory from a single platform.

- Insights & reporting: advanced insights and detailed reporting into sales trends, inventory levels and product performance, empowering you to make informed choices about reordering, promos and business strategy.

As your business grows, a sophisticated, flexible inventory management system like Lightspeed can grow with you. Learn more.

10. FIFO and LIFO

First in, first out (FIFO) and last in, first out (LIFO) are two inventory management methods that govern which inventory is sold first. With FIFO, the oldest inventory items are sold or used first, and it’s primarily used to manage perishable foods like food or pharmaceuticals, which need to be sold before they expire.

With LIFO, you sell the newest industry first. Why? Because when prices are rising, using the more expensive, recently acquired stock to calculate your cost of goods sold (COGS) can give you a more accurate picture of your company’s financial health. It also lowers your profits (on paper, anyway), which can result in significant tax savings, but only in the United States.

11. Consignment inventory

Consignment inventory is a supply chain model in which a retailer (consignee) agrees to sell a supplier’s product, but the supplier (consignor) owns the product until it’s sold to a customer. Because the retailer doesn’t actually buy the inventory until it sells the products, it can return whatever doesn’t sell to the supplier.

This model offers significant advantages to both parties, including greater market reach for suppliers and lower financial risk for retailers.

Successfully selling stock on consignment depends on a solid consignment agreement. This is the contract between the consignor and consignee that clearly outlines the terms of the agreement, including payment terms, duration and the rights and responsibilities of each party. Basically, it clearly spells out who does what and who pays for what.

12. Economic order quantity (EOQ)

Economic order quantity (EOQ) is a calculation companies use to figure out the optimal order quantity for a product that will meet demand while minimizing total inventory costs—from ordering costs (like shipping and handling) to holding costs (like storage and insurance).

There are several variations of the formula used to calculate EOQ, but here’s one of the most popular:

| EOQ = √ [ (2 x order cost x annual demand in units) / holding costs] |

To calculate a product’s EOQ with this formula, you’ll need a basic understanding of algebra and the following variables:

- Annual demand in units. Check your historical order and sales data to determine how many units you sell per year.

- Order cost = shipping and handling costs per order

- Holding costs (per year, per unit) = total cost of holding unsold units (e.g. warehousing fees, insurance, etc.)

If it’s been a while since you’ve had to find the square root of something, here’s a free square root calculator that can do it for you.

13. Perpetual inventory management

Perpetual inventory uses software like point of sale (POS) systems and scanners to update inventory counts automatically with every sale, purchase or return. This inventory management technique provides accurate stock counts in real time, helping retailers improve inventory accuracy, demand forecasting and decision-making.

In a perpetual inventory system, every product is assigned a tracking code, such as a barcode or RFID code. These are the basic steps to implement perpetual inventory tracking in your warehouse or retail store:

- Labeling: attach a unique barcode or RFID tag to each product in your inventory. This tag contains important information about the item, including its quantity and location.

- Scanning: whenever you sell, receive or move an item, scan its tag. This updates your inventory count in real-time, so you always know what’s in stock and where to find it.

- Inventory management software: sophisticated inventory management software updates stock levels automatically as transactions occur, allows you to view and track inventory across multiple locations and sales channels, and lets you manage your entire operation from a single unified platform.

- Analyzing key metrics: use advanced insights into your key performance metrics to optimize inventory, spot trends and make informed decisions about reordering and promotions.

14. Minimum order quantity (MOQ)

Minimum Order Quantity (MOQ) refers to the minimum number of units that you must order from your supplier at any one time. These are set by the supplier to ensure they can cover their production costs and make a profit on the sale. MOQs can be frustrating for retailers who may feel “forced” to order more than they need, but at the end of the day, nobody got into this business to lose money.

If your supplier has implemented an MOQ for one or more of the products you want to order, use demand forecasting to determine if you’ll need at least that number of units. If the difference between your ideal order quantity and your supplier’s MOQ is negligible, then it probably makes sense to move forward with the order. If not, you may have to look for a different supplier, or try to negotiate a compromise with your desired supplier.

If you’re a retailer who sells wholesale to other retailers, you might have to set your own MOQs. While there’s no set formula for calculating MOQs, you’ll want to consider the following variables:

- Demand: use historical data to forecast demand. Consider factors like seasonality, lead time and competition.

- Holding costs: otherwise known as inventory carrying costs, holding costs may include warehousing fees, insurance fees, energy costs, etc.

- Break-even point: how many units you need to sell to cover your costs. Be sure to take all your overhead costs into account, from the price of materials to labor and storage costs.

15. Bulk shipping

Bulk shipping involves buying and transporting large quantities of products at once. This reduces per-unit transportation costs—and can often get you a discount from your supplier—because the total shipping cost is spread across a larger number of items.

That said, bulk shipping can also result in overstocking, overcrowding, product damage, and longer handling times. Businesses also need adequate storage space and handling equipment to manage these large shipments efficiently, the costs of which may surpass what you’re saving in transportation costs.

16. Batch tracking

Batch tracking refers to an inventory management technique that makes it easier for businesses to monitor and trace groups of products as they move through the supply chain, from production all the way to customers.

It works by grouping together products with similar properties within a larger group of products. These product groups are assigned a unique batch or lot number at the production stage. These batch/lot numbers store important product details, such as production date, materials used, expiration dates, history of quality assurance checks, etc.

As products move through the supply chain, their batch number is scanned and logged at each stage. If quality issues arise or a product recall is required, batch tracking makes it much easier to identify the source of the problem, locate and pull the affected products and identify any other products that could have been affected.

Bottom line

Effective inventory management is non-negotiable in today’s retail landscape, and helps retailers ensure they have the right products in stock at the right time, minimizing lost sales and reducing excess inventory.

By implementing techniques like FIFO, automated reorder points, safety stock, and perpetual inventory management—among others—you can improve your overall efficiency, free up capital, reduce unnecessary costs and boost customer satisfaction.

So, if your current inventory management method is giving you a headache, it might be time to take one or more of these techniques for a spin.

Want to learn how tools like Lightspeed point of sale (POS) and inventory management software can help you save a ton of time on inventory management and gain greater accuracy and control? Book a demo with one of our POS experts today.

FAQs

What is the most commonly used inventory management method?

FIFO (First In, First Out) is one of the most widely used inventory management methods. It ensures that older stock is sold first, helping businesses manage inventory turnover, avoid stockpiling outdated products and maintain an efficient flow of merchandise.

What is the best inventory method for a small business?

For small businesses, the First-In, First-Out (FIFO) method is often the best inventory management choice. It’s simple to use, ensuring older stock sells first, which helps maintain product freshness and helps prevent getting stuck with tons of outdated inventory. Pairing FIFO with an inventory management software that tracks sales both in-store and online can help small businesses stay organized, automate reorder alerts and manage stock levels with ease and accuracy.

How do you overcome poor inventory management?

To overcome poor inventory management, use inventory management software for real-time tracking, set up automated reorder alerts and implement regular stock audits. These techniques of inventory management can greatly enhance accuracy and efficiency.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.