Barcodes are an essential part of doing business as a retailer. So are SKUs. They can feel like second nature, a quintessentially understood part of the entire process. But for employees new to operating a retail store and managing inventory, it can be difficult to understand how barcodes work, as well as UPCs and SKUs, what purposes they serve and how they differ.

That’s what we’re going to clear up in this post. Learn what they are, the differences between them, what purpose they serve and their benefits.

In this post, we’ll cover:

- What is a barcode?

- How do barcodes work?

- Types of barcodes

- The benefits of using barcodes

- What is a UPC?

- What is the purpose of a UPC

- What are the advantages of UPCs

- UPCs vs. SKUs

- Comparing barcode scanners

- The future of barcoding

- How to create your own barcodes

Generate barcodes, fast

Tired of manually managing your inventory? Create unlimited unique barcodes for your inventory today with our free barcode generator tool. It's easy to use and compatible with all scanners.

What is a barcode?

A barcode is an image that consists of a series of parallel black and white bars that can be read by a barcode scanner.

Barcodes are applied to products to quickly identify them. Among their many uses, barcodes are typically used in retail stores as a part of the purchasing process, in warehouses to track and manage inventory and on invoices to help with accounting.

What is a barcode scanner?

A barcode scanner (also referred to as a barcode reader) is a device that captures and decodes the information contained by a barcode. Typically, barcode scanners consist of the following four components:

- Light source: This helps the barcode read and accurately decode the information contained in a barcode.

- Lens: This scans the barcode.

- Photoconductor: This translates optical impulses into electrical ones.

- Decoder: This analyzes the barcode’s data and sends it to the scanner’s output port.

After capturing the information, barcode scanners link to a host computer or tablet and transmit that information in real-time, without additional human intervention. This helps retailers automate data collection processes and reduce human errors like inventory tracking and processing point of sale transactions.

How do barcodes work?

A barcode is a way to encode information into a visual pattern (those black lines and white spaces) that a machine (a barcode scanner) can read.

The combination of black and white bars (also referred to as elements) represents varying text characters that follow a pre-established algorithm for that barcode (more on the types of barcodes later).

A barcode scanner will read this pattern of black and white bars and translate them into a line of text that your retail point of sale system can understand.

Types of barcodes

There are two types of barcodes: 1-dimensional (1D) and 2-dimensional (2D).

These types can be further divided into sub-types, like the 1D universal product codes (UPC) or the 2D QR codes.

1-dimensional (1D) barcodes

1D barcodes are a series of black and white bars that can store information like a product’s type, size and color.

You can find 1D barcodes as UPCs on a product’s packaging. This helps track packages through package delivery service providers like UPS and FedEx, the US Postal Service and Canada Post.

2-dimensional (2D) barcodes

2D barcodes are more complex than 1D barcodes. They can include more information than just text, like price, inventory levels and even a product image. QR codes are an example of a 2D barcode, as are the similarly shaped Aztec codes, typically used on tickets for flights or concerts.

While not all barcode scanners can read 2D barcodes, Lightspeed Retail POS is compatible with several wireless barcode scanners that support 2D barcodes.

| 1D Barcodes | 2D Barcodes | |

| Appearance | Black and white bars | Graphical, typically blocks or a mix of blocks and bars |

| Data Storage | Store text relating to type, size and color | Can store text, dynamic data and images |

| Reading Device | Read with a barcode scanner | Read with an imager scanner |

What about 3D barcodes?

You may have heard about 3D barcodes, the newest barcodes to hit the market. They’re essentially 2D barcodes, but instead of the information being encoded by an image, 3D barcodes use 3D shapes like engraving. They require specialized scanners and are not typically found in retail contexts.

The benefits of using barcodes

While barcodes were originally developed to speed up the sales and transaction process, they come with several other benefits.

Improved accuracy

Using a barcode to process a product’s data is much more accurate than having a sales associate manually enter that data, which is prone to human error.

Real-time data

Because of the speed at which the information is processed, data about inventory levels or sales is available immediately.

Reduced training requirements

Thanks to a barcode scanner’s ease of use (just point and click), employees don’t need much training on how to use one.

Better inventory management

With improved accuracy and real-time data, retailers benefit from faster cycle counts and more accurate inventory turnover estimations.

Low cost of implementation

Generating barcodes is quick and simple. And thanks to improved transaction speed, as well as the improved accuracy of inventory and sales data, retailers can anticipate savings post-implementation.

What is a universal product code (UPC)?

A universal product code (UPC) is a code that’s printed on a retail product’s packaging to help it be identified. They are primarily used in North America, but find use around the world for ecommerce as well.

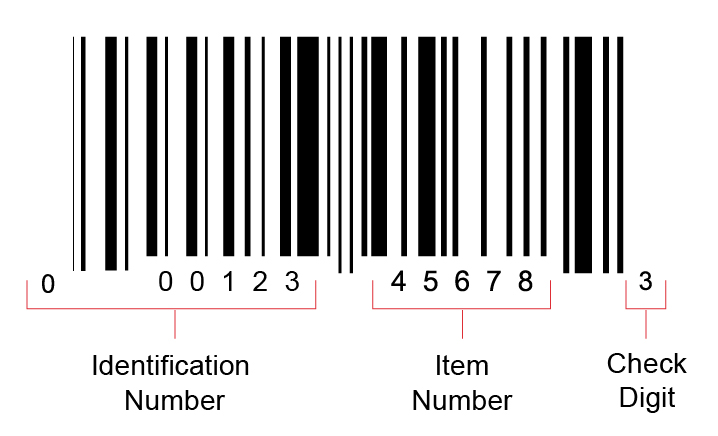

There are two parts that make up a UPC: the machine-readable barcode (which is a series of black bars) and the unique 12-digit number located beneath the barcode.

Parts of a UPC

To get a UPC to use on products, a company needs to apply through GS1 US (the Global Standards Organization), which manages and assigns UPCs in the US.

After paying the application fee, GS1 assigns a six-digit manufacturer identification number; that becomes the first six digits of the UPC for all of the company’s products and identifies the item’s manufacturer.

The subsequent five digits of the UPC are the item number, which identifies the product itself. Each company should have a person responsible for issuing item numbers, ensuring that the same number isn’t used more than once and that numbers associated with discontinued products are no longer used.

Most consumer products have several variations based on their size, color, etc. Each variation needs its own item number. For example, a box of medium-sized t-shirts will have a different item number than a box of the same t-shirt in size small.

The last digit of a 12-digit UPC is the check digit. It’s found by adding and multiplying several of the UPC code’s numbers to confirm to the barcode scanner that the UPC is a valid one. If the check digit code isn’t correct, the result is that the UPC code won’t scan properly.

What’s the purpose of a UPC?

UPCs make it easy to identify a product by its name, item type, size and color when it’s scanned at the checkout. They were initially created to make grocery store checkouts faster, but nowadays they’re also commonly used to help track inventory in retail stores and warehouses.

The advantages of a UPC

There are several advantages—both for businesses and consumers—of using UPCs.

Since UPCs help barcode scanners identify a product and its cost, UPCs help improve checkout speed. They effectively remove the need to manually input a product’s information.

UPCs also improve inventory tracking and management. They help merchants know when they need to stock more of a particular product either on their shelves or in stock more in their warehouse.

If ever there’s an issue with a product, UPCs help merchants find the customers that purchased that product, contact them and issue a recall.

UPCs vs. SKUs

While UPCs and stock keeping units (SKUs) share some similarities, they aren’t the same thing.

A UPC is a universal product code; it’s meant to identify a product regardless of where it was sold. For example, if you buy a t-shirt online or through a local retailer that also sells the same product, that t-shirt will have the same UPC.

A SKU, however, is an internal product inventory code that’s unique from one company to the other. If you were to compare the SKU of the same product at two different stores, you’d see that they were different.

If you’re confused as to whether you’re looking at a UPC or SKU, the UPC symbol is the barcode label or bar coding on the back of a product, whereas the SKU is typically found on a store’s unique shelf pricing.

If you were to try looking up a product online, using the product’s UPC will help you find it across numerous retailers, whereas the SKU would only find the product under the business using that specific SKU.

UPCs can be valuable for suppliers and manufacturers to track the inventory they sell to different retail merchants, whereas SKUs are valuable for merchants to track and manage their inventory in a way that’s unique to their business.

Both SKUs and UPCs are advantageous for retailers: SKUs for their customizability and UPCs for their universality. Many businesses use a mix of UPCs and SKUs. To learn how to add items to your inventory with UPCs and SKUs in Lightspeed POS, check our retail support page that covers the topic in greater detail.

| UPC | SKU | |

| Full Form | Universal Product Code | Stock Keeping Unit |

| Purpose | To identify a product regardless of where it was sold. Used for tracking inventory sold to different retail merchants. | An internal product inventory code unique to each company. Used by merchants to track and manage their inventory in a way that’s unique to their business. |

| Usage | The same UPC is used for a product across different retailers. Found as the barcode label on the back of a product. | SKU is unique from one company to another and found on a store’s unique shelf pricing. |

| Searchability | Using the UPC can help find a product across numerous retailers. | Using the SKU can only find the product under the business using that specific SKU. |

| Value | Valuable for suppliers and manufacturers for tracking inventory. | Valuable for merchants to track and manage inventory in a unique way. |

| Advantages | Universality across different retailers. | Customizability and uniqueness to each business. |

Comparing barcode scanners: laser vs. charged coupled device (CCD) vs. camera-based

When selecting a barcode scanner, retailers have three primary types to consider: Laser, CCD and camera-based scanners.

Laser scanners, recognized for their precision and speed, are ideal for high-volume environments. They can easily read barcodes at long distances, making them suitable for supermarkets and warehouses. The cost for these devices ranges from moderate to high, reflecting their efficiency and durability.

CCD scanners, on the other hand, are better for short-range scanning. They’re cost-effective, making them a good choice for small retail settings or when the budget is a primary concern. Their technology captures barcode images from close distances but cannot read from screens, limiting their use in certain modern retail environments.

Camera-based scanners offer the most versatility, capable of reading 1D barcodes and and 2D QR codes from any angle, including off screens. This makes them perfect for retailers integrating mobile payments or loyalty programs. While they tend to be the most expensive, their flexibility and functionality justify the investment, especially in dynamic retail spaces where adaptability is key.

The future of barcoding technology: RFID, customer scanning and 3D barcodes

Some retailers have recently begun experimenting with the integration of Radio Frequency Identification (RFID) technology with traditional barcodes. This hybrid approach not only speeds up the checkout process by allowing multiple items to be scanned simultaneously but also enhances inventory management through real-time tracking.

The development and use of smartphone-compatible barcodes, particularly QR codes, is also making waves. By enabling consumers to scan items with their mobile devices, retailers can offer more interactive shopping experiences, such as instant access to product information, reviews and comparisons.

Finally, there are 3D barcodes. So-called 3D barcodes are essentially advanced 2D barcodes that can store data both horizontally and vertically, allowing for more information in a compact space. As they grow in popularity, retailers will be able to use them for inventory management, tracking and enhancing customer engagement through quick scanning with smartphones while being able to store more data.

How to create your own barcodes

- Step 1: decide on the type of barcode that suits your needs. 1D barcodes are for basic inventory tracking, while 2D barcodes are for more detailed information.

- Step 2: if needed, obtain a unique manufacturer identification number from a GS1 member organization, ensuring your barcodes are globally unique.

- Step 3: generate barcodes with a tool like our free online barcode generator. This tool allows you to input your product information and generate a barcode that can be printed and attached to your items.

- Step 4: test your barcodes with your scanners to ensure compatibility and readability. This proactive step guarantees that your inventory processes run smoothly, enhancing efficiency and accuracy.

Frequently asked questions about barcodes

How does the coding of barcodes work?

Barcodes represent data by varying the spaces and widths of parallel lines (in 1D barcodes) or patterns of squares, dots, hexagons and other geometric shapes (in 2D barcodes). This data is then decoded by a scanner.

Can two products have the same barcode?

Ideally, no. Each product should have a unique barcode (specifically the UPC or EAN) to avoid confusion and ensure accurate tracking and inventory management.

Do barcode scanners read the black or white bars?

Barcode scanners read both the black bars and the white spaces in between them. The contrast between the black and white allows the scanner to decode the information.

Can I create my own barcodes?

Yes, you can create your own barcodes for internal use (like inventory tracking with SKUs). For retail purposes where a unique identifier is needed (like UPCs), you should register for a unique code through a GS1 member organization.

What do the first two digits of a barcode mean?

In an EAN-13 or UPC barcode, the first two digits often represent the country code of the manufacturer, although this is not strictly about geographic location but more about where the manufacturer’s business is registered.

How can the information in a barcode be read?

The information in a barcode is read by a scanner, which uses light to translate the barcode into a digital format that computers can understand. The scanner sends this data to a computer or cash register for processing.

Are barcodes always 13 digits?

Not always. EAN-13 barcodes are 13 digits long, but UPC-A barcodes are 12 digits, and other barcode formats can vary in length.

What is the standard encoding for barcodes?

The standard encoding for retail barcodes is either UPC (Universal Product Code) or EAN (International Article Number). UPC is common in North America, while EAN is used internationally. There are also other standards like Code 128 and QR codes, depending on the use case.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.