Inventory management is the foundation of any successful retail business. Stock availability, avoiding overstock and accurate tracking aren’t just operational tasks—they directly affect cash flow, customer experience and overall efficiency. But even for seasoned business owners,inventory management can be a constant challenge.

The complexity only grows as businesses add more locations or sales channels. Real-time tracking, clear processes and accurate forecasting aren’t nice-to-haves—they’re non-negotiable for staying competitive. Without the right systems, even small missteps can lead to expensive mistakes or lost opportunities.

The key is knowing what the common challenges are and using solutions that scale with your business.

Grow your retail business.

Streamline inventory, suppliers, teams and stores with Lightspeed's all-in-one platform. From intuitive POS and stock management features to powerful reporting, Lightspeed gives you the tools you need to grow.

20 common inventory management challenges

Rapidly changing customer demand

Customer demand isn’t static—it shifts fast. Stockouts mean missed sales, but overstock ties up cash that could be used elsewhere.Predicting trends and adjusting inventory levels quickly is the only way to stay ahead.

Inaccurate data and analysis

Bad data leads to bad decisions. Mistakes in inventory records cause over-ordering, understocking and wasted resources. Real-time tracking keeps everything accurate so you can plan with confidence.

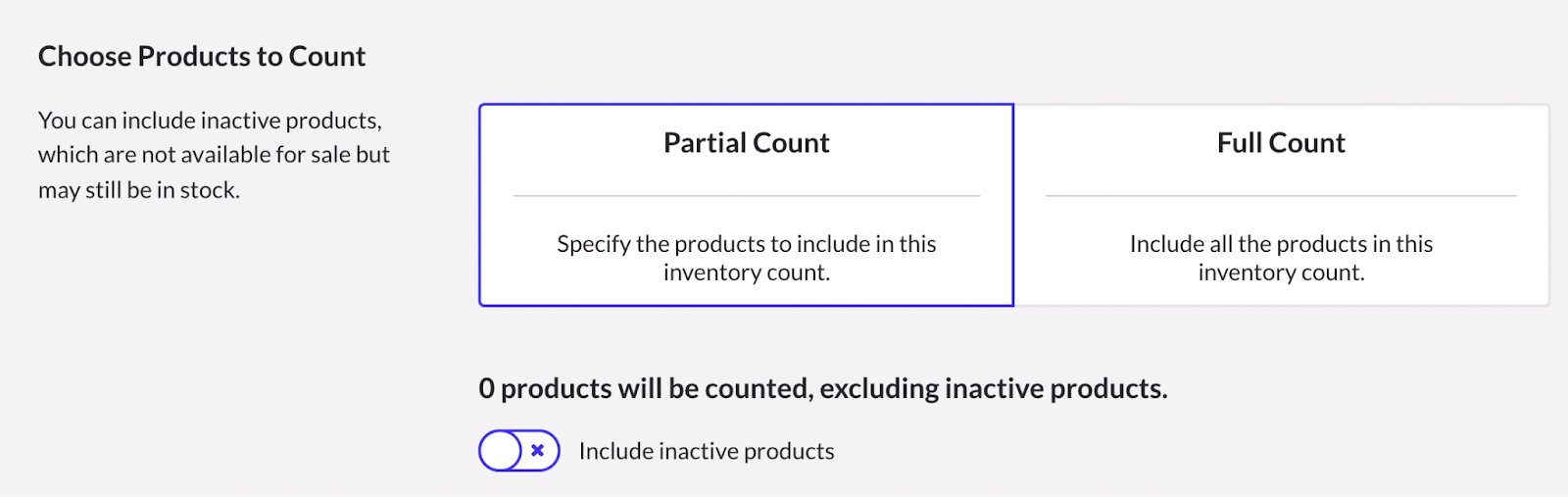

It’s also important to make sure that you and your team stay on top of physical inventory counts and audits. That way, your inventory levels are always up to date.

One tool to consider is Lightspeed Scanner, which lets teams count items by simply scanning barcodes into the app. Scanner turns your mobile device into a powerful stock counting tool that streamlines physical counts and enables multiple employees to work simultaneously.

Reordering delays

Late reorders throw everything off—empty shelves, lost sales and frustrated customers. Relying on manual tracking often means missed reorder points.

The solution? Use a retail management solution that lets you set safety stock levels and reorder points so products can be replenished before they run out.

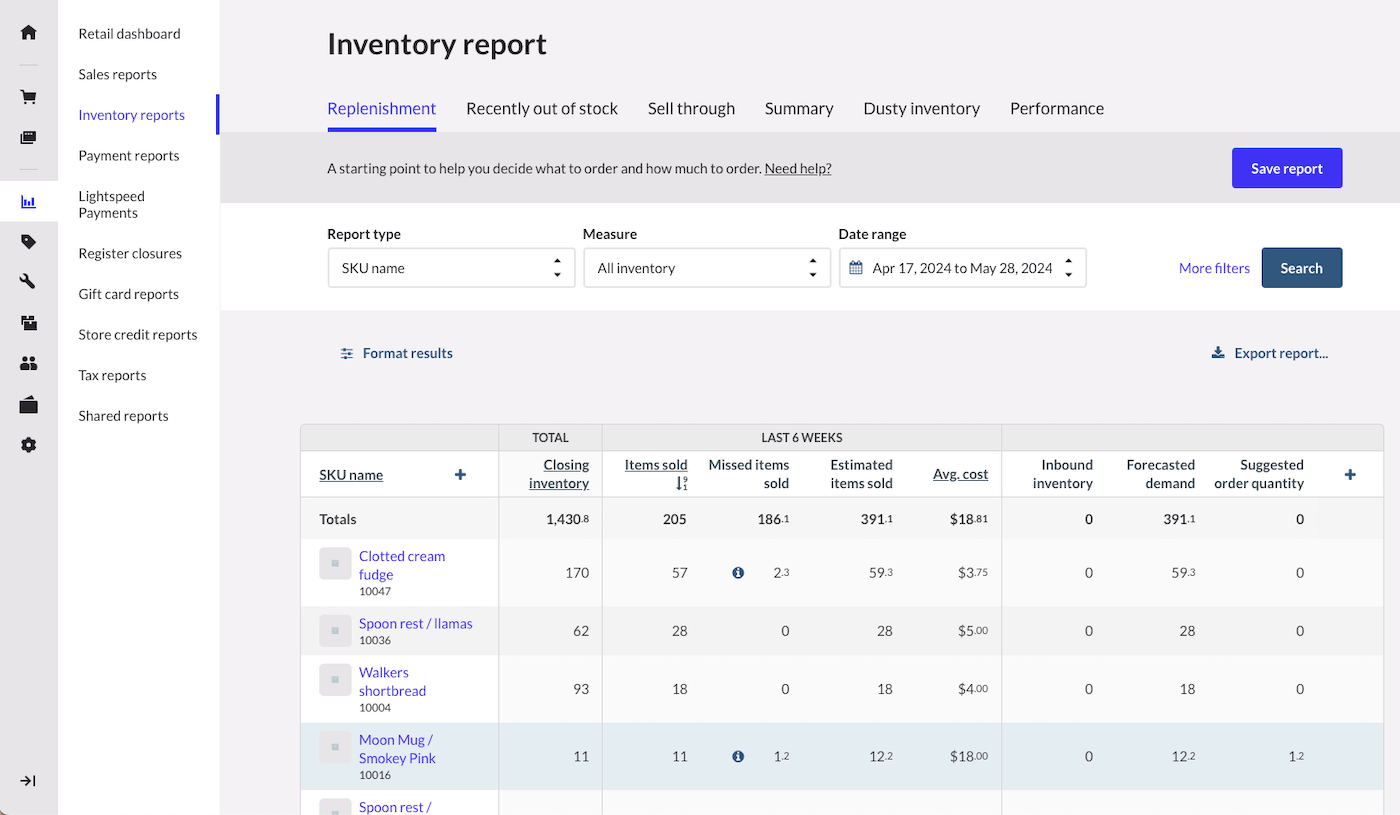

Lightspeed Retail has built-in reorder points and restock levels that automatically populate orders when stock is low, saving you time and ensuring you never run out of bestsellers. By setting reorder points for each product and outlet, you can proactively restock before running low, keeping sales flowing smoothly.

Poor production planning

When production doesn’t match sales, the results are messy. Overproduction clogs up storage, while underproduction leaves orders unfulfilled.

One way to combat this is by aligning production schedules with real-time inventory data to make sure supply matches demand. Doing so prevents costly stock imbalances and ensures products are available when customers need them—keeping sales steady and operations efficient.

Inventory defects and waste

Defective products don’t just cost money—they waste valuable space and resources. Batch and serial number tracking makes it simple to pinpoint and isolate issues before they spiral.

If defects stem from vendor or supplier issues, having a structured quality control process is key. Regularly inspecting incoming shipments, setting clear quality standards with suppliers, and leveraging vendor performance reports can help identify recurring issues.

Another tip? Negotiating better terms with vendors—like refunds for defective goods or improved packaging—can also minimize losses.

Ordering errors

Manual ordering often leads to mistakes—too much, too little or the wrong items altogether. Automating the process ensures accuracy, so inventory stays on track without guesswork.

You can sidestep this inventory misstep by automating purchase orders in your business. Choose a solution that keeps your POs and inventory in sync.

Lightspeed NuORDER is a great example of a platform that automates supplier information and keeps your product data accurate. It syncs thousands of products with your POS, allowing retailers to import pre-loaded details—like UPCs, MSRP, descriptions and images—directly from suppliers. This eliminates manual entry errors and speeds up purchase order creation.

Lisa Bobb, owner of Squash Blossom Boutique uses Lightspeed NuORDER to streamline her purchase order workflows. Doing so allows her to create POs 80% faster.

“It used to take me about 25 minutes to do my PO data entry,” she says. “Now, I can get it done within about five minutes.”

Capital tied up in unused inventory

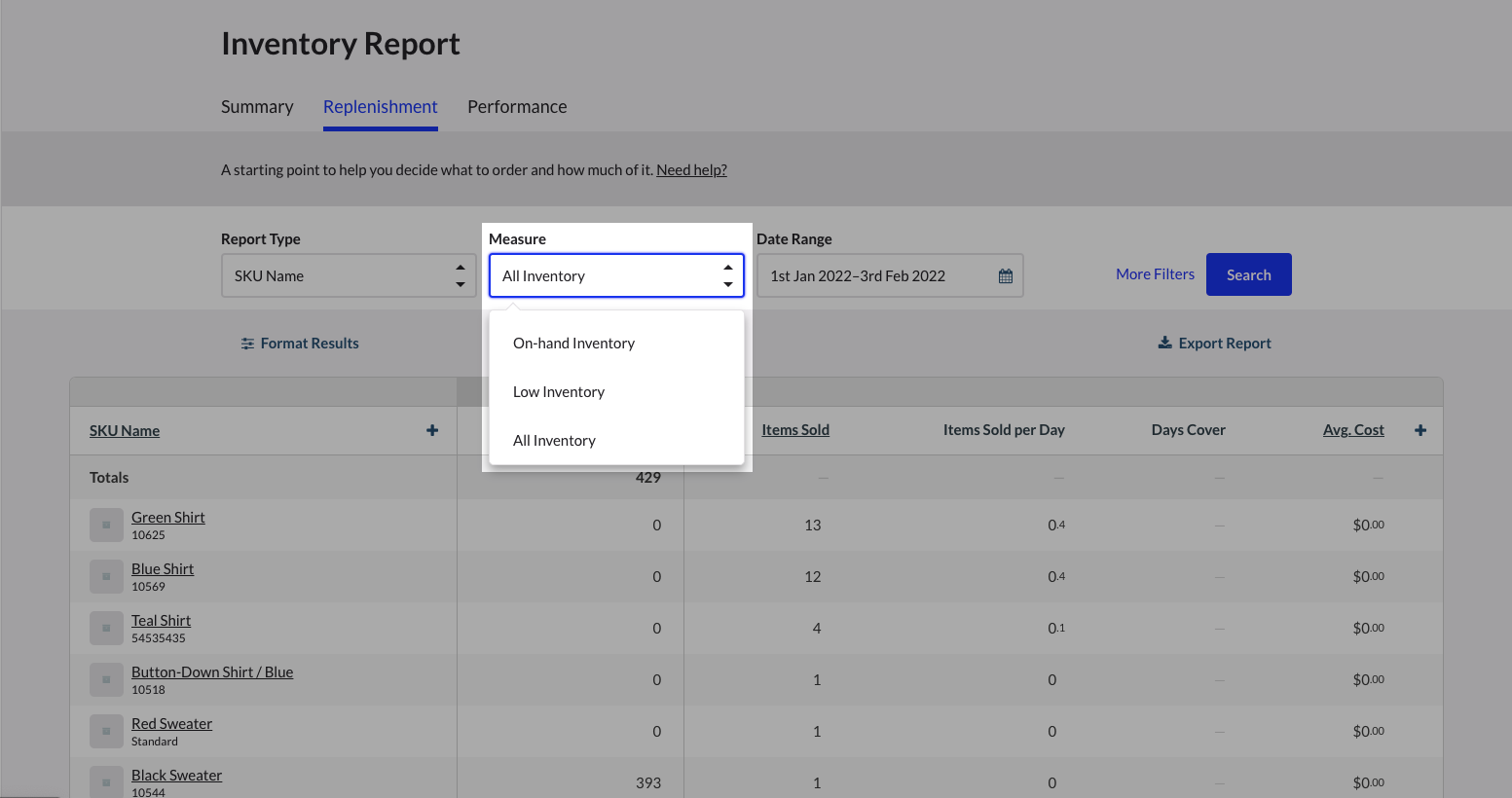

Excess stock ties up cash your business could use for growth. Identifying slow-moving products helps clear out what’s not selling and frees up working capital for what is. You can do this by generating product performance reports that shed light on sales and inventory turnover.

For best results, choose inventory tracking software that lets you filter data by product category, brand, supplier and other parameters so you can pinpoint slow-moving inventory, make informed markdown decisions and optimize reordering.

Overstocking

Too much inventory doesn’t just take up space—it increases storage costs and risks obsolescence. Balancing stock with optimization tools preventsoverstock while keeping shelves ready for sales.

There are several tactics to help you avoid surplus stock, including:

- Setting reorder points and restock levels

- Monitoring sales trends

- Implementing just-in-time (JIT) inventory

- Using demand forecasting

- Running strategic promotions

- Optimizing supplier relationships

Improper inventory storage

Disorganized storage damages products and slows down fulfillment. Poor practices also increase shrinkage.

That’s why it pays to have a clear system for organizing inventory. It ensures items are stored properly and easy to access.

Evaluate your stockroom and product storage practices. From there, implement standardized labeling, logical shelving arrangements, and clear inventory zones to streamline operations and reduce errors.

For example, a clothing retailer might organize inventory by size and color, with clear signage and bin labels, ensuring staff can quickly find items. A grocery store could use a first-in, first-out (FIFO) system by placing newer stock behind older items to reduce waste and prevent expired products from being sold.

Multiple stock storage locations

Managing inventory across multiple locations gets complicated fast. Without centralized visibility, it’s hard to keep things running smoothly. A unified system connects all locations so you can track everything in one place.

Pro tip: you can use a cloud-based inventory management software to manage all your stores from one centralized platform. Opt for a system that enables you to transfer stock and oversee multiple locations so you can stay on top of inventory across your entire operation.

Lack of transportation capacity

When transportation is unreliable, shipments get delayed and supply chains fall apart. While inventory tools can’t solve logistics on their own, integrating them with transport management ensures better coordination.

Lack of warehouse space

Cluttered warehouses slow operations and create inefficiencies. Tracking underperforming items helps free up space by clearing out what’s not moving.

Consider implementing vertical storage solutions, optimizing shelving layouts, and using clear labeling to maximize space efficiency.

Another step to take? Regularly audit inventory to identify slow-moving or obsolete stock so they’re not taking up space in your warehouse. You can run promotions or bundle deals to clear them out.

Additionally, reevaluating supplier order quantities can prevent overstocking and keep storage areas organized.

Lack of attention to fast-moving items

High-demand products need constant attention—ignoring them means missed sales. Tracking sales trends ensures you always know what’s flying off the shelves and when to restock.

As mentioned above, it’s best to set up automated alerts for low stock levels so you can reorder fast-moving items before they run out.

You should also regularly review sales reports to identify peak demand periods and adjust purchasing accordingly.

Reliance on manual processes

Manual inventory management is slow and riddled with errors. Automating repetitive tasks speeds things up, reduces mistakes and lets teams focus on what matters most.

Start by digitizing inventory tracking with barcode scanners or RFID systems. These solutions minimize human error and streamline stock counts. From there, automate purchase orders based on preset reorder points ensures you never run out of essential products.

Finally, integrating inventory management with sales and fulfillment systems provides real-time stock updates, reducing discrepancies.

Lack of required packaging

Running out of packaging materials when you need them delays shipments and frustrates customers. Tracking packaging alongside products guarantees you’re always prepared to fulfill orders.

Monitor packaging inventory just like product stock by setting reorder points for essential materials such as boxes, tape, and protective fillers. Streamline ordering by working with reliable suppliers and negotiating bulk discounts to avoid last-minute shortages. Consider sustainable packaging options that are cost-effective and readily available. Regularly reviewing order volume trends helps anticipate packaging needs, ensuring you have the right materials on hand to keep fulfillment running smoothly and customers satisfied.

Delaying inventory counting

Putting offinventory counts leads to discrepancies and lost control. Regular, real-time counts keep everything accurate without the need for catch-up audits.

Pro tip: implement cycle counting, where small sections of inventory are counted regularly instead of conducting a full count all at once. Assign responsibility to team members to ensure accountability and consistency.

Depending on your store, you may want to consider scheduling counts during slower business hours to avoid disruptions.

Pausing warehouse operations

Stopping everything to manually check inventory disrupts workflows and kills productivity. The solution? Continuous tracking eliminates the need for pauses so operations don’t grind to a halt.

Aside from rolling inventory counts to keep operations running smoothly while maintaining accuracy, use real-time tracking systems that update stock levels as items move in and out.

Also, train staff to conduct spot checks during regular shifts instead of halting workflows for large-scale audits. Streamlining inventory management with clear processes ensures that stock remains accurate without disrupting order fulfillment, keeping business operations efficient and uninterrupted.

Lack of data transparency

When inventory data isn’t accessible, decision-making suffers. Real-time reporting keeps everything visible, giving teams the information they need to act quickly.

Without clear visibility, stock discrepancies go unnoticed, leading to costly mistakes. A centralized inventory system ensures that all team members—from warehouse staff to management—have access to the same up-to-date information. Setting user permissions allows the right people to track stock levels, monitor sales trends, and make informed purchasing decisions. Regularly reviewing inventory reports helps identify patterns, prevent stockouts, and optimize storage, ensuring that businesses stay agile and responsive to demand.

Poor integration with other software and systems

Disconnected tools create inefficiencies and bottlenecks. Seamless integration between inventory systems and other platforms keeps information flowing smoothly across the business.

When systems don’t communicate, inventory discrepancies, delayed order fulfillment and data silos become inevitable. Choosing software that integrates with accounting, ecommerce and supply chain management tools ensures accurate reporting and smooth operations. Automated data syncing reduces manual input errors and keeps stock levels updated in real time.

What’s more, regularly auditing system connections and workflows helps identify gaps, ensuring that every part of the business operates efficiently without unnecessary delays or miscommunication.

Lack of supply chain agility

Rigidsupply chains can’t keep up with sudden changes in demand or disruptions. Flexible inventory tools help businesses adapt quickly, avoiding downtime and missed opportunities.

When supply chains lack flexibility, stock shortages and overages become costly problems. Building relationships with multiple suppliers provides backup options in case of delays. Keeping safety stock for high-demand items reduces the risk of running out during disruptions. Demand forecasting, based on real-time sales data, helps businesses anticipate shifts and adjust orders accordingly. Periodically reviewing supplier performance and renegotiating terms ensures that sourcing strategies remain agile and responsive to market conditions.

Bottom line

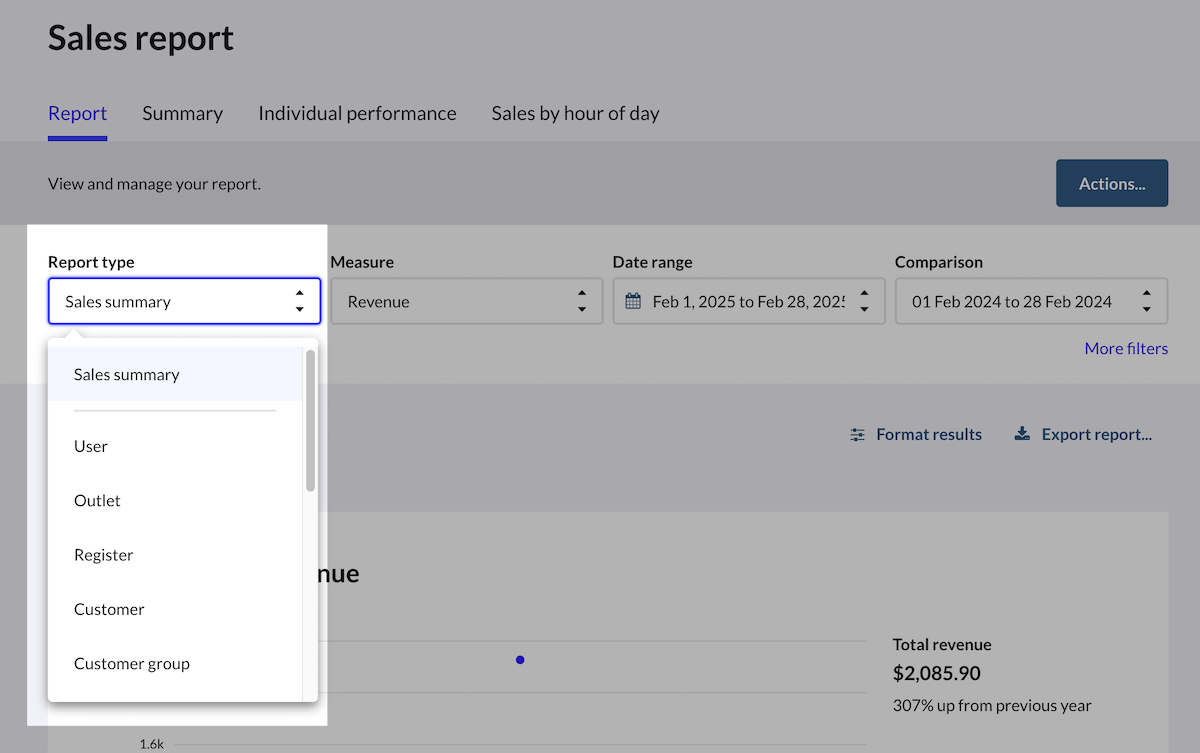

Inventory management issues—like inaccurate tracking, overstocking, or poor demand forecasting—can disrupt operations and stall growth. The right tools make all the difference. Real-time visibility, streamlined multi-location oversight, and automation are key to fixing these challenges. APOS system built for inventory management keeps everything running smoothly while giving you more time to focus on growing your business.

With forecasting tools, centralized data, and automation, managing stock no longer feels like guesswork. You can prevent cash flow problems, cut down on waste, and keep customers happy with reliable stock availability. It’s about better efficiency, better margins, and better results across every location.

Watch a demo to see how the right POS system can take your inventory management to the next level.

FAQs

What integrations does Lightspeed POS offer for inventory management?

POS systems are designed to work seamlessly with tools like accounting software, ERP platforms and ecommerce solutions. These integrations connect your systems, cutting down on manual data entry and reducing errors. For inventory management, common integrations include supplier catalogs, shipping tools and analytics platforms—keeping everything streamlined and in sync.

How does Lightspeed POS improve data accuracy in inventory management?

Accurate inventory data depends on two things: real-time tracking and centralized updates. POS systems handle both by automating stock counts, syncing sales across all channels and creating audit trails for every transaction. The result? Clean, reliable records that make it easier to forecast demand and avoid costly mistakes.

Can Lightspeed POS handle multi-location inventory management?

Managing inventory across multiple locations doesn’t have to be complicated. A strong POS system tracks stock in real-time, no matter how many stores or warehouses you’re running. With a centralized dashboard, you can monitor inventory levels, move items between locations and set reorder points—all while keeping everything accurate and efficient.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.